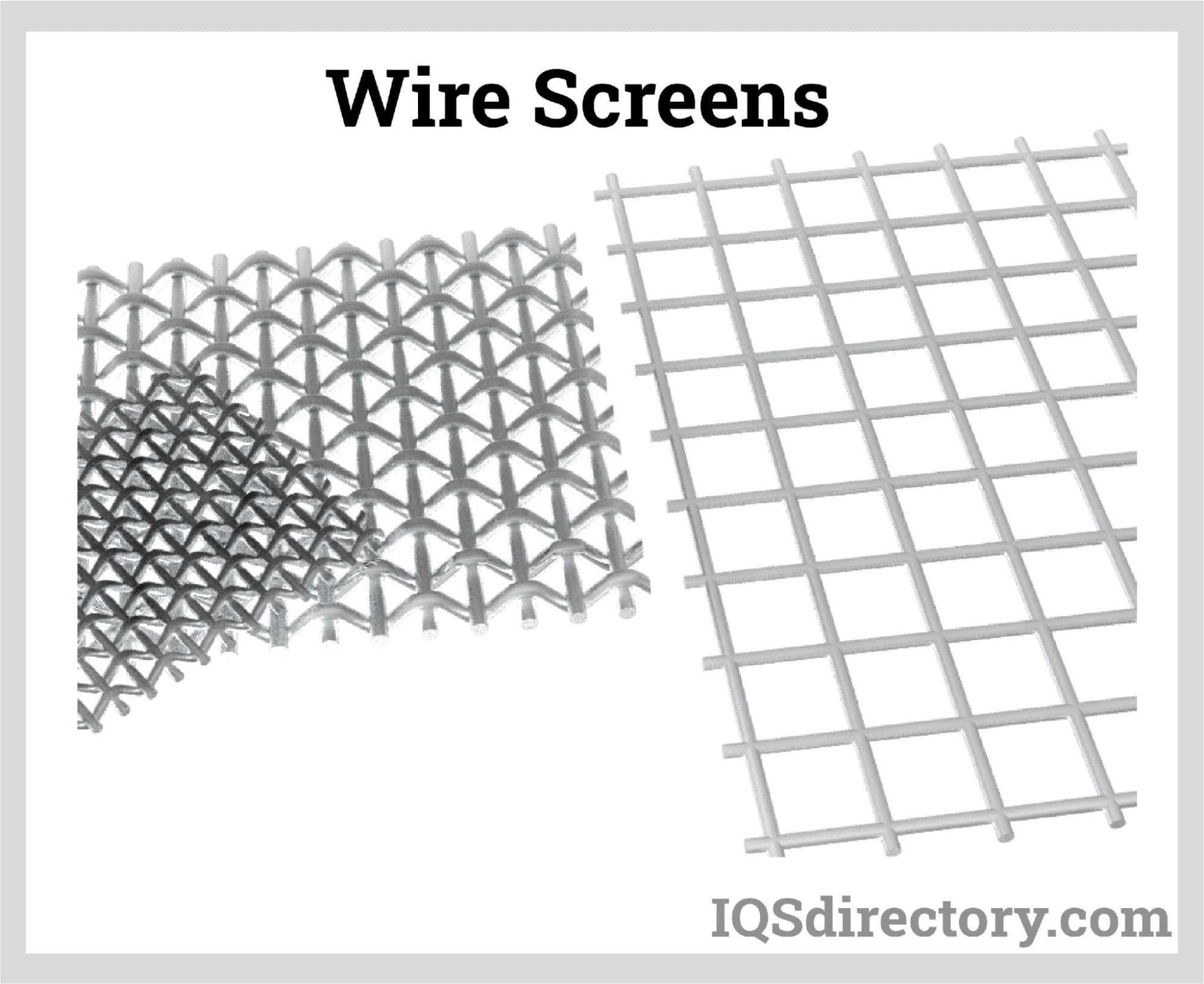

Wire screens are ideal for aggregate processing, washing applications, cement manufacturing, asphalt plants, and mining applications. Wire screens, or wire mesh screens, are a woven metal fabric with either square or rectangular “working holes” formed between wires. Although some wire screens are used to improve the atmosphere of a home, wire mesh materials are often employed to provide equipment protection, filtration, or better safety. Read More…

We’ve been a leading manufacturer and distributor of wire cloth/mesh for 70 years, sourcing and stocking North America’s largest selection of wire cloth products – over 5000 in our warehouse. We offer processing capabilities such as precision cutting, calendering, heat treating, cleaning and coating and weave domestically most alloys including brass, copper, Hastelloy, Monel and others into ...

Banker Wire is your quality-driven manufacturing partner for woven and welded wire mesh used in architectural and industrial applications. Our manufacturing expertise has been refined for over a century, bringing unmatched customization, quality, and service to our customers. Our products embody our commitment to providing the widest variety of wire cloth at an unbeatable value. Nowhere else will ...

For over 45 years, UWC has supplied quality mesh products for numerous industries with distinct applications. We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles. Our fabrication services comprise shearing, slitting and stamping options. In addition, we produce baskets, trays, cylinders,...

Marco Specialty Steel is a leading-supplier of wire cloth, wire cloth screens and wire mesh. Our warehouse maintains a wide range of wire cloth products in a variety of material grades and styles. We offer wire cloth in full rolls, cut-to-size pieces, slitting, circle cutting, blanking and stamping.

Hoyt Wire Cloth is a family-owned business that has been serving a variety of markets for over 50 years. We have experience producing wire cloth for industries such as coal, landscaping, concrete, gravel & sand, and more. Our line of wire mesh products includes self-cleaning screens, perforated plate, screening accessories, and more. If you have a design in mind call us and will manufacture what...

Since 1885, Phoenix Wire Cloth has been a wire cloth manufacturer of industrial wire cloth, welded wire cloth, wire mesh, stainless steel wire cloth and filter cloth. Phoenix Wire Cloth produces wire cloth for fences as well as safety and security equipment and supplies.

More Wire Screen Manufacturers

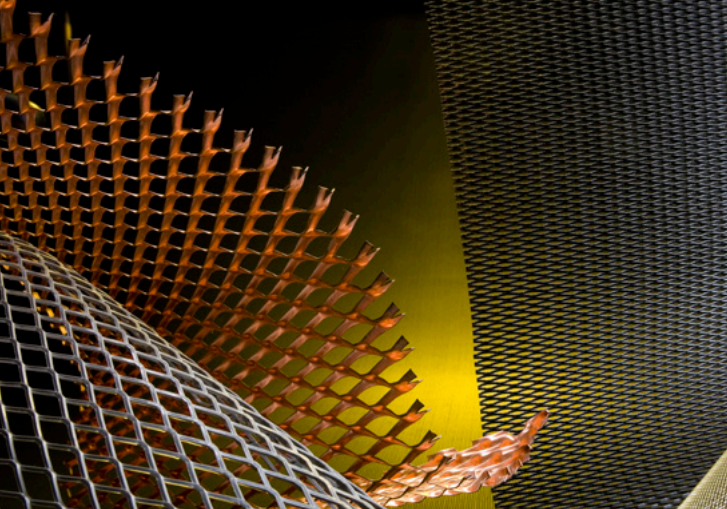

Wire screen is made of wires previously corrugated in both directions. As a result, they get an uneven surface, precise apertures, exceptional granulometric accuracy, and strong resistance. Moreover, because the material must cross over itself, the surface's roughness ensures remarkable sieving efficiency while maximizing screening and production.

Applications of Wire Screens

- Farm, garden, and agricultural uses ranging from fencing to soil and grain sifters

- Window enclosures

- Building and construction

- Pet and critter control barriers and cages

- Window and safety guards

- Infill panels

- Filtration and separation equipment

Types of Wire Screen

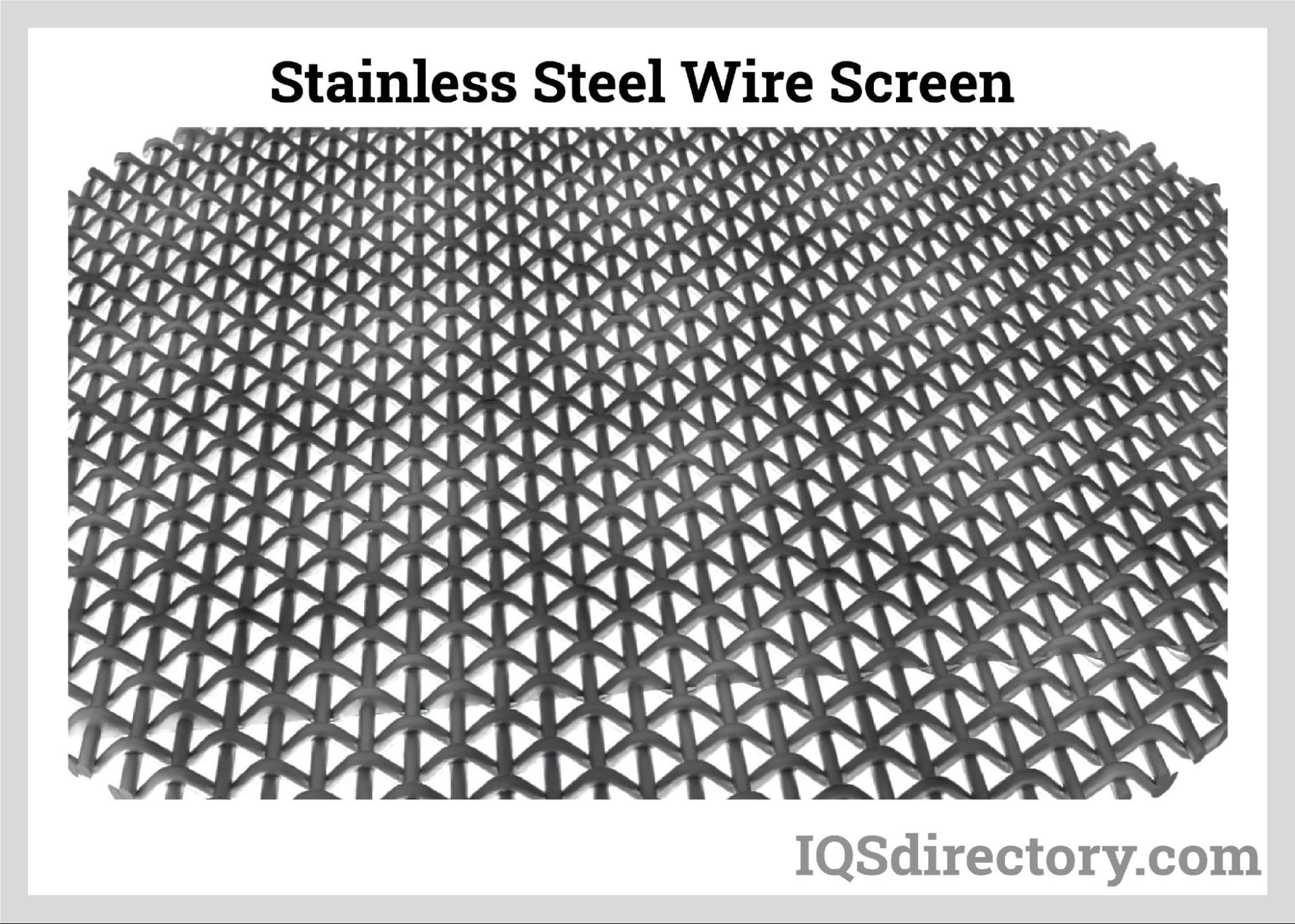

Stainless Steel Wire Screen

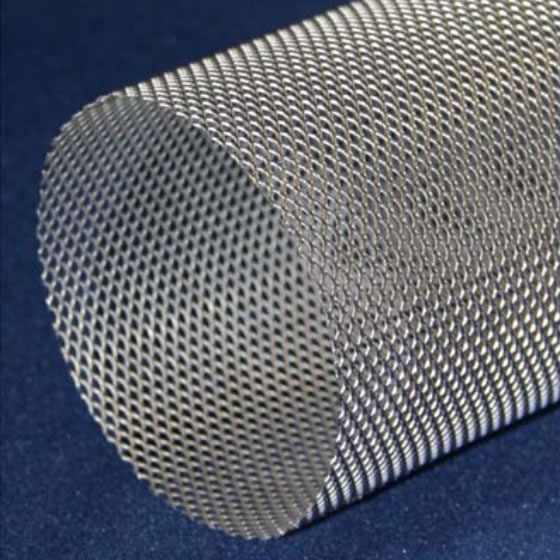

Metal that is woven includes stainless steel wire mesh. The material, valued for its remarkable strength and long lifespan, is crucial for various commercial and residential applications and use across many sectors. It is made using wires that range in diameter from 0.0008 inches to 0.047 inches. Stainless steel wire mesh is made from stainless steel wire on specialized weaving machines.

It is used in nearly every industry sector, including chemicals, pharmaceuticals, plastics, mechanical engineering, mining, and food processing. The sectors that utilize stainless steel screens include petroleum and chemical environmental protection, mining, aerospace, paper, electronics, metallurgical, food production, and pharmaceuticals for filtration and separation.

Stainless steel wire mesh is required in various sectors because it is strong and corrosion-resistant. This material is used in filters, automobile grills, and air vents, among other things. One of the main factors influencing consumers to choose stainless steel mesh is its versatility.

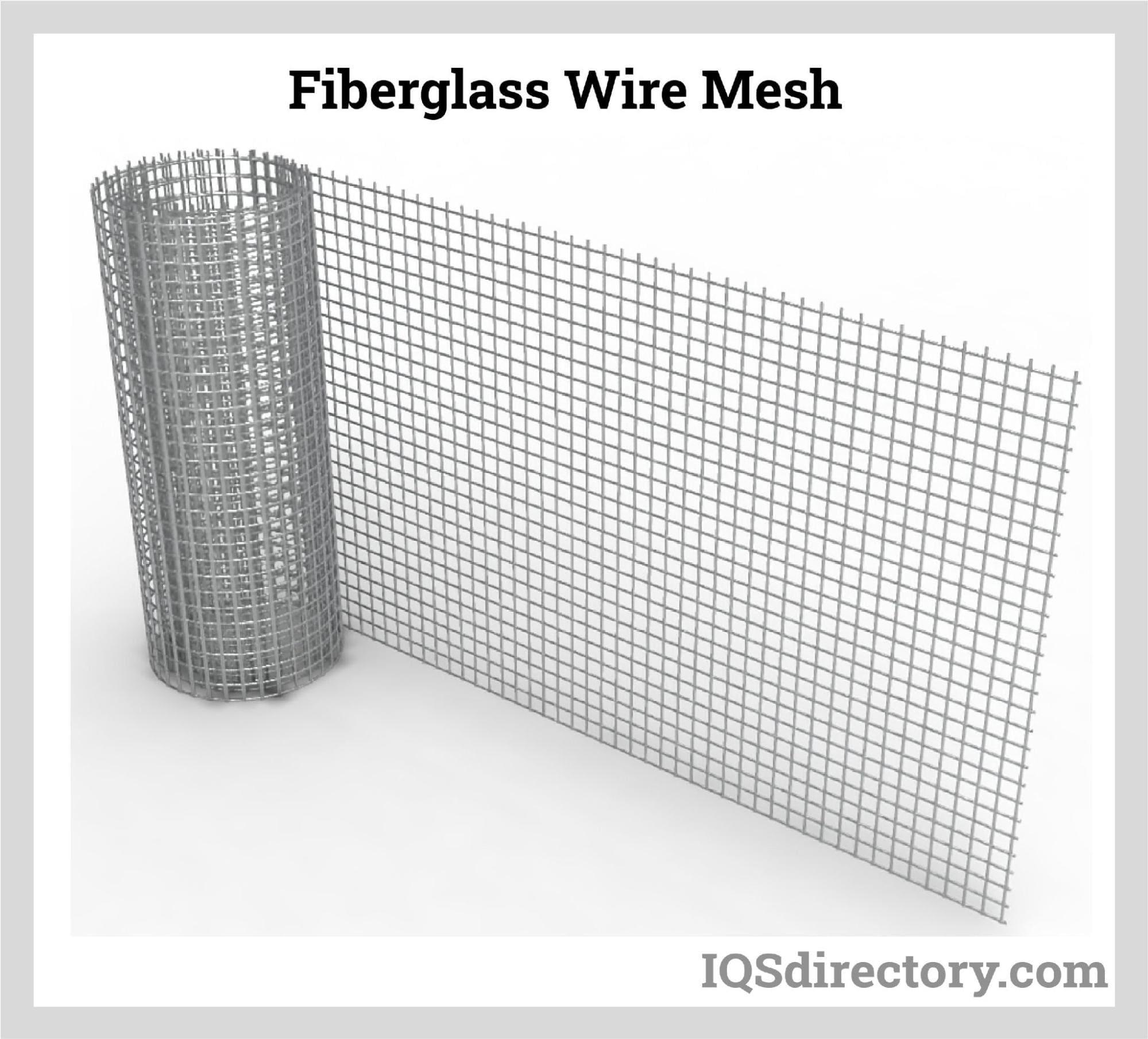

Fiberglass Wire Screen

Fiberglass is formed into a single screen wire that will be used to make wire mesh for window screens. It is vinyl-coated before being weaved into a mesh screen with vertical and horizontal strands. It has a protective vinyl coating to ensure it is brightly colored, flexible, and won't rust, corrode, or stain. The screen's mesh size and fiber-strand diameter will determine how much light and ventilation it provides.This is an adaptable, affordable, and simple screen to install.

A screen made of fiberglass won't fold, dent, or unravel. This is the most popular window and door screening type used for new construction and window screen replacement. Another name for fiberglass bug screens is fiberglass window screens. The simplest to use and least priced window screen mesh is fiberglass. For windows, patios, and pool enclosures, the insect screen is utilized the most frequently. Due to its superior external visibility, the color charcoal is the most preferred.

This widely used substance has been around for a while. It may be molded into intricate shapes because it is lightweight, robust, and not very brittle. Fiberglass can be laid out randomly, woven into a cloth, or flattened into a sheet. It is incredibly adaptable. Fiberglass screen mesh is a good option for inexpensive, useful, sturdy, and ecologically friendly screens.

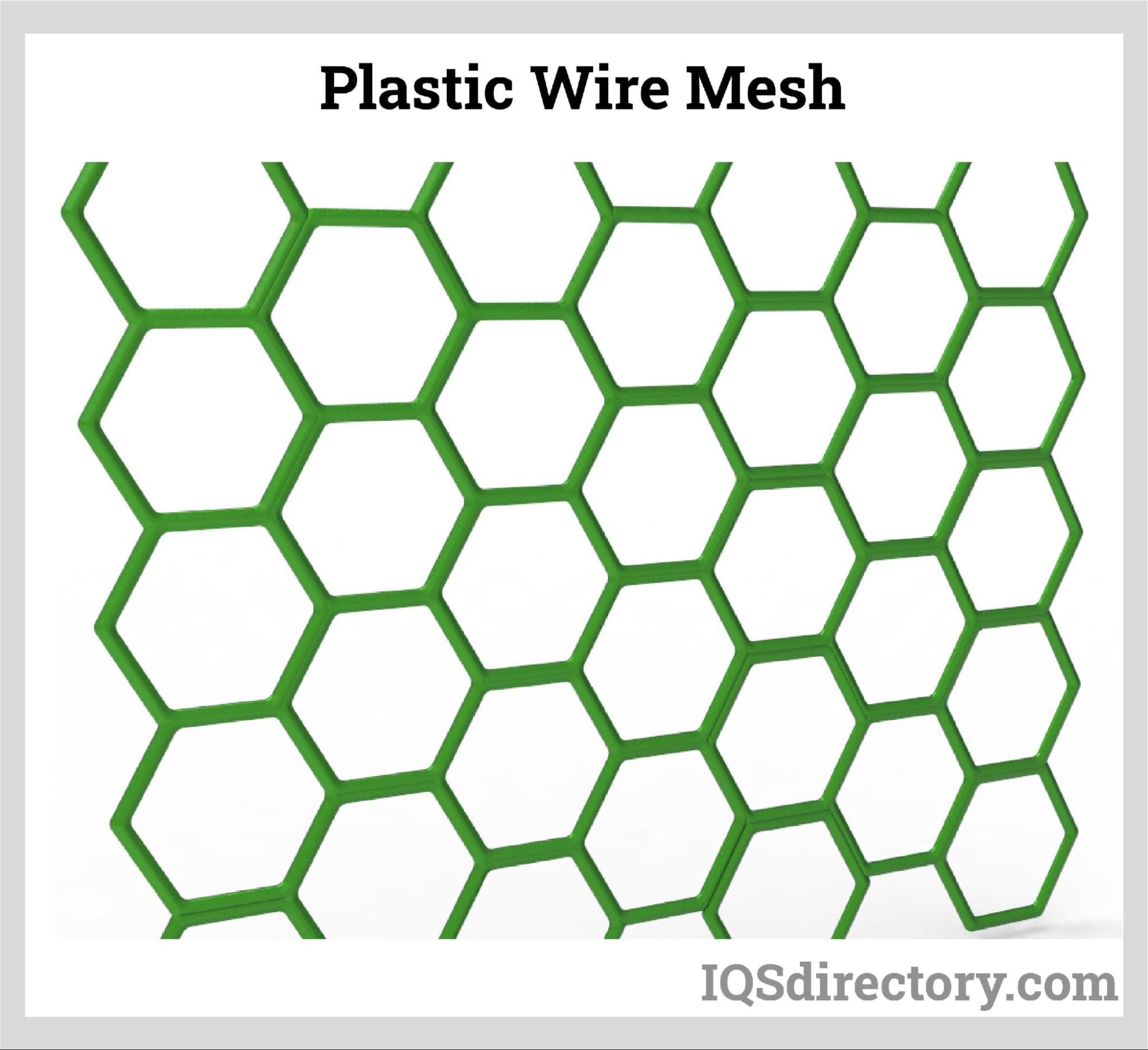

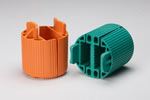

Plastic Wire Screen

This mesh is used for property and farm fencing, sports fencing, agricultural fencing, balconies and railings, and road barriers. Plastic wire screen has a smooth finish and efficiently prevents rusting. Plastic mesh is primarily utilized in the oil, chemical, aquatic breeding, vehicle back cushions, Simmons® mattresses, trampoline safety nets, anti-bird, anti-gnat wire, stop-burn wire mesh, and roadbed mesh industries.

Numerous base resins can be used to create a plastic mesh. The two most prevalent resin options for plastic wire screens are polyethylene (PE) and polypropylene (PP), both providing versatility at an affordable price. In addition, polypropylene is rugged and unusually resistant to numerous chemical solvents, bases, and acids.

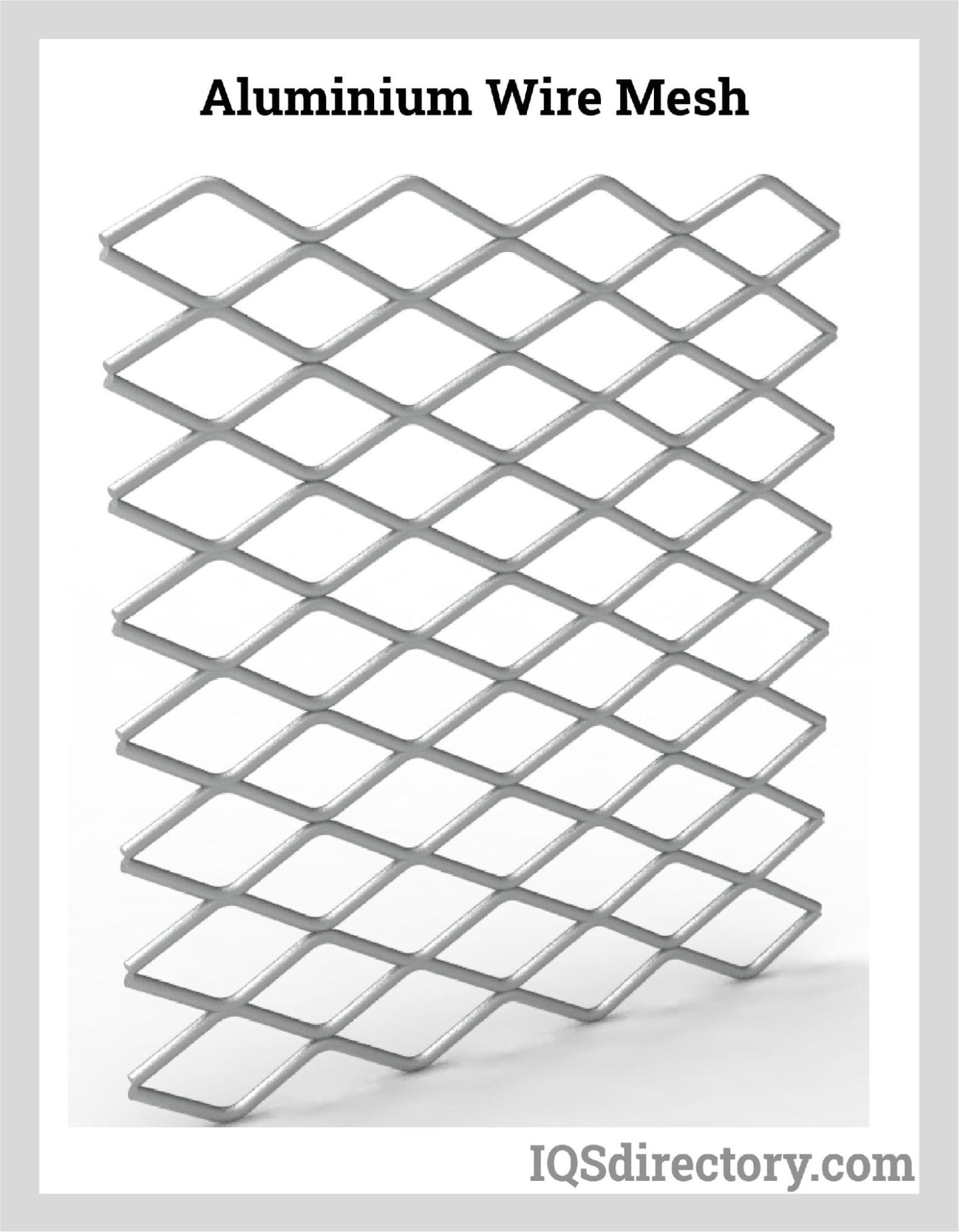

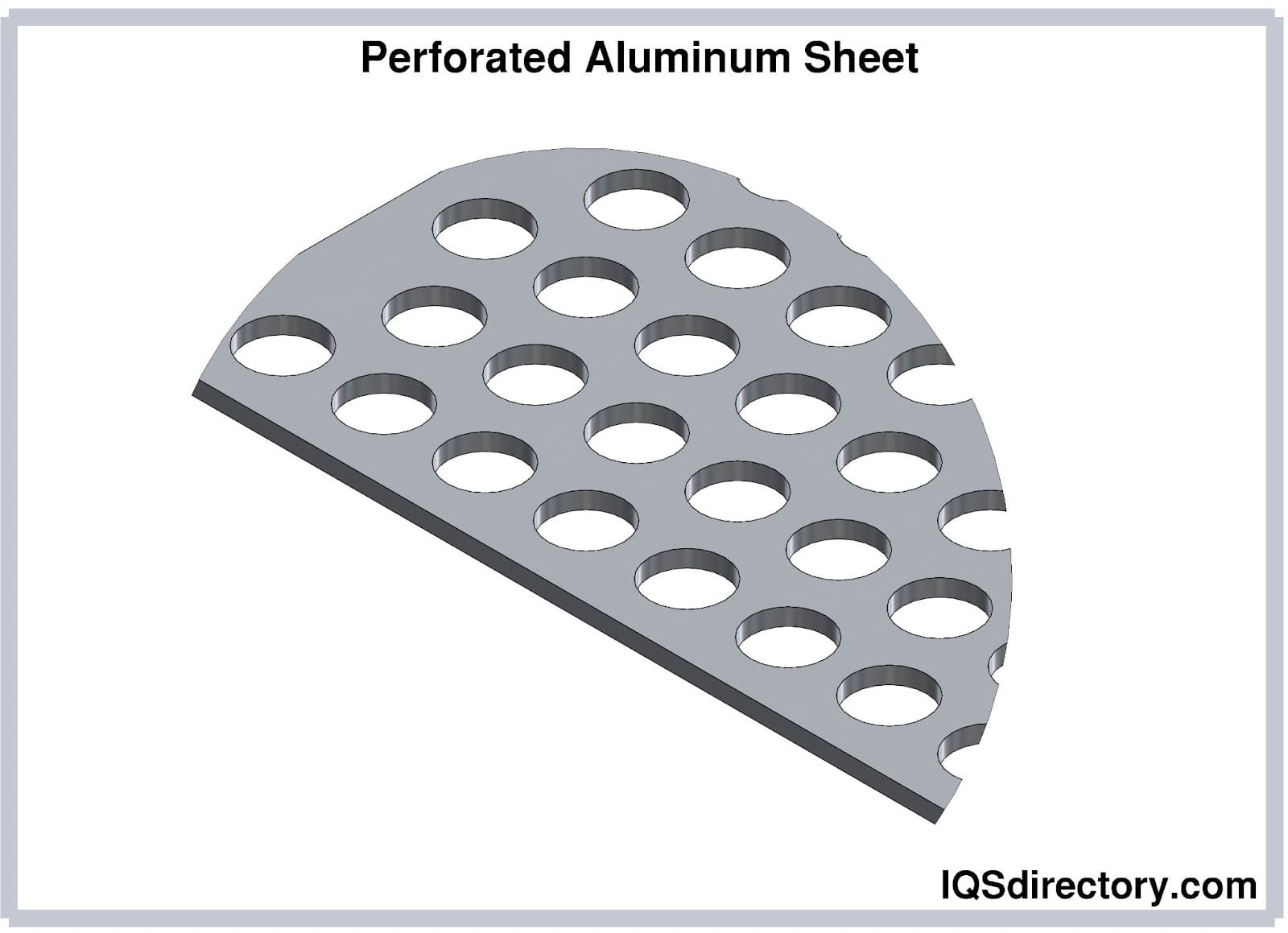

Aluminum Wire Screen

Aluminum wire mesh is a sheet of simple square-woven mesh made from the highest quality aluminum wire. Similar to stainless steel mesh in terms of corrosion resistance but lighter and softer. The aluminum wire mesh sheet is easily bent and shaped with negligible spring back. Aluminum wire mesh is ideal for lightweight screening applications like air vents and personal audio headsets since it weighs around one-third as little as stainless steel mesh with the same requirements.

Benefits of Wire Screens

- Traction-enhancing qualities

- Excellent conductivity

- Simplicity in installation

- Wonderful light filtration

- Flexibility in application

Choosing the Right Wire Screen Supplier

To ensure you have the most positive outcome when purchasing wire screen material from a wire screen supplier, it is important to compare several companies using our directory of wire screen suppliers. Each wire screen supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each wire screen business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple wire screen companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services