Most filter screens have a square weave and are not welded at cross points because the pattern is too fine. Read More…

We’ve been a leading manufacturer and distributor of wire cloth/mesh for 70 years, sourcing and stocking North America’s largest selection of wire cloth products – over 5000 in our warehouse. We offer processing capabilities such as precision cutting, calendering, heat treating, cleaning and coating and weave domestically most alloys including brass, copper, Hastelloy, Monel and others into ...

Banker Wire is your quality-driven manufacturing partner for woven and welded wire mesh used in architectural and industrial applications. Our manufacturing expertise has been refined for over a century, bringing unmatched customization, quality, and service to our customers. Our products embody our commitment to providing the widest variety of wire cloth at an unbeatable value. Nowhere else will ...

For over 45 years, UWC has supplied quality mesh products for numerous industries with distinct applications. We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles. Our fabrication services comprise shearing, slitting and stamping options. In addition, we produce baskets, trays, cylinders,...

Marco Specialty Steel is a leading-supplier of wire cloth, wire cloth screens and wire mesh. Our warehouse maintains a wide range of wire cloth products in a variety of material grades and styles. We offer wire cloth in full rolls, cut-to-size pieces, slitting, circle cutting, blanking and stamping.

Hoyt Wire Cloth is a family-owned business that has been serving a variety of markets for over 50 years. We have experience producing wire cloth for industries such as coal, landscaping, concrete, gravel & sand, and more. Our line of wire mesh products includes self-cleaning screens, perforated plate, screening accessories, and more. If you have a design in mind call us and will manufacture what...

Since 1885, Phoenix Wire Cloth has been a wire cloth manufacturer of industrial wire cloth, welded wire cloth, wire mesh, stainless steel wire cloth and filter cloth. Phoenix Wire Cloth produces wire cloth for fences as well as safety and security equipment and supplies.

More Filter Screen Manufacturers

Filter screens are open yet protective barriers that are simple in design, but very effective in removing dirt, dust and other particles from any liquid. These screens take the idea of strainers or window screens and apply it to filtration systems of all kinds. The food and beverage manufacturing, petro-chemical, agricultural, water purifying, mining, pharmaceutical and oil industries use filter screens to purify and clean many different types of liquids, including irrigation water, potable water, oil, alcoholic beverages and juices.

One of the most common places to find a filter screen is in faucets. They are small, round pieces of woven wire mesh situated at the faucet opening to catch any debris and dirt that made it through the drinking water system. Filter screens are reusable, long lasting, and very resistant to a variety of temperatures and moisture. They won't rust, unravel or wear out easily. If that does happen, filter screens are very inexpensive and easy to replace.

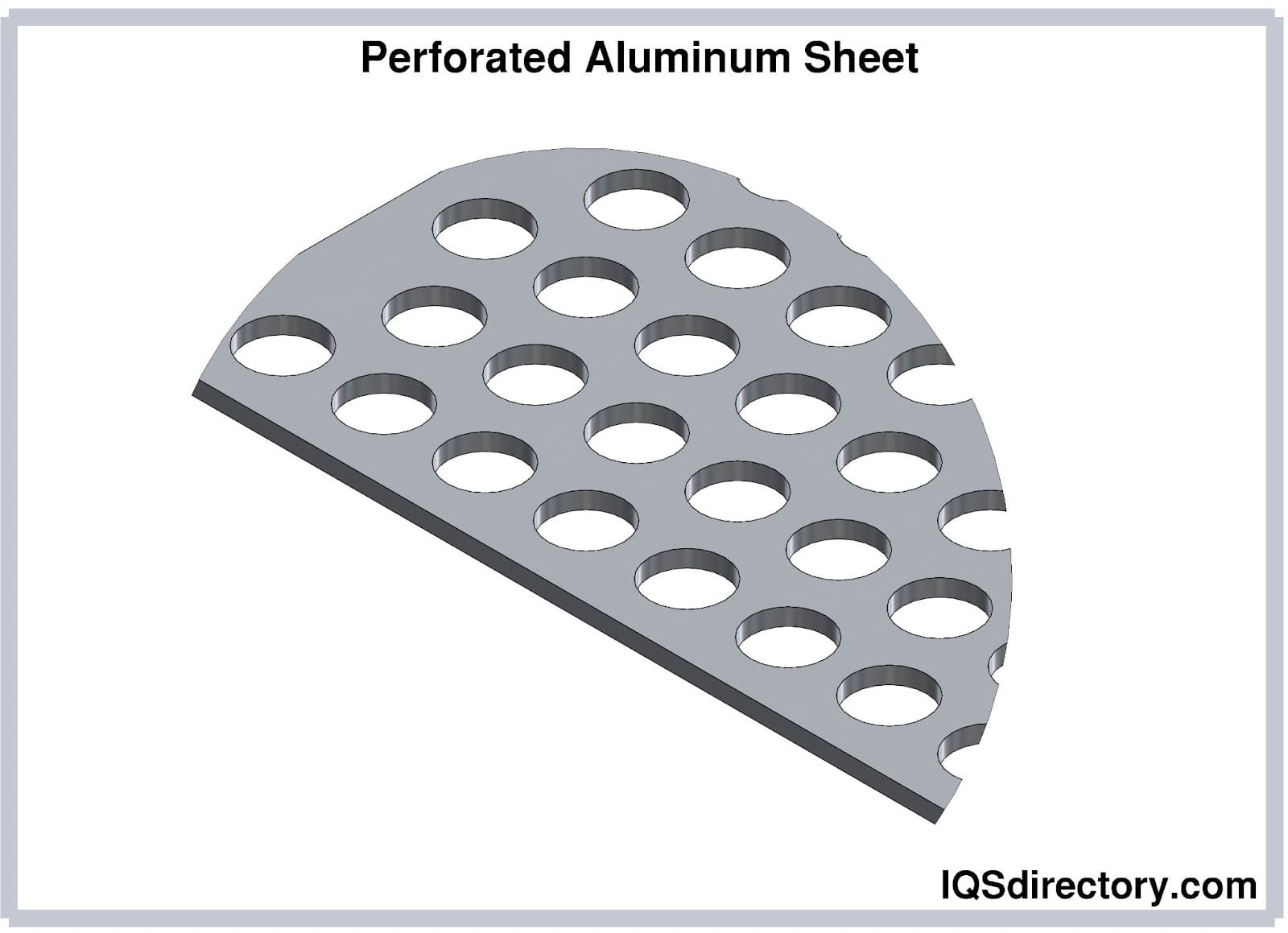

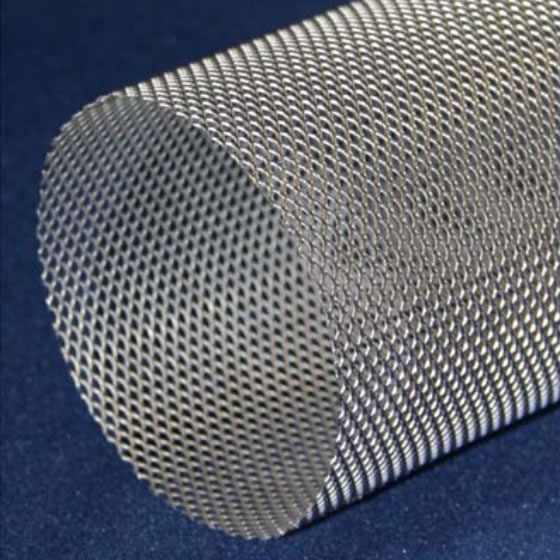

Filter screens are made of very fine metal wires, usually made of aluminum because of its light weight and high durability, or stainless steel because of its smooth, highly resistant finish. The wires themselves are manufactured through the drawing process, which forces a wire through a smaller die, thus decreasing its diameter. This may be done several times to achieve the ultra-thin measurements of filter screen wires. Sets of perpendicular wires are then woven together by interlacing with each other over and under in an even pattern. The result is a fine gauge, tight, durable wire cloth that lets water and liquid through but stops even the tiniest of particles.

After the weaving process, which produces the wire cloth in large sheets or rolls, it is galvanized to increase durability and rust resistance. During this process, the wire cloth is hot dipped in molten zinc, which causes the metal's strength and resistance properties to enhance and strengthen. Once dry, the wire cloth will not oxidize if exposed to water for long periods of time. All filter screens must be routinely cleaned out. They are continuously used, and the particles and contaminants they stop tend to build up behind them.

Cold Headed Parts

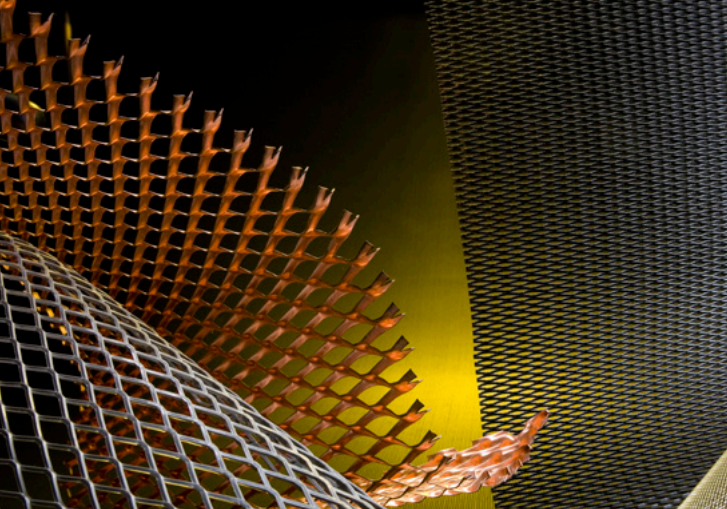

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services