The extraordinary adaptability of wire cloth, commonly referred to as wire mesh or wire fabric, is well recognized. The matrix of wires that are placed at 90-degree angles is what makes wire mesh unique. Almost any metal, including stainless steel, copper, aluminum, nickel, molybdenum, and many others, can be used to create wire cloth products. Read More…

We’ve been a leading manufacturer and distributor of wire cloth/mesh for 70 years, sourcing and stocking North America’s largest selection of wire cloth products – over 5000 in our warehouse. We offer processing capabilities such as precision cutting, calendering, heat treating, cleaning and coating and weave domestically most alloys including brass, copper, Hastelloy, Monel and others into ...

Banker Wire is your quality-driven manufacturing partner for woven and welded wire mesh used in architectural and industrial applications. Our manufacturing expertise has been refined for over a century, bringing unmatched customization, quality, and service to our customers. Our products embody our commitment to providing the widest variety of wire cloth at an unbeatable value. Nowhere else will ...

For over 45 years, UWC has supplied quality mesh products for numerous industries with distinct applications. We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles. Our fabrication services comprise shearing, slitting and stamping options. In addition, we produce baskets, trays, cylinders,...

Marco Specialty Steel is a leading-supplier of wire cloth, wire cloth screens and wire mesh. Our warehouse maintains a wide range of wire cloth products in a variety of material grades and styles. We offer wire cloth in full rolls, cut-to-size pieces, slitting, circle cutting, blanking and stamping.

Hoyt Wire Cloth is a family-owned business that has been serving a variety of markets for over 50 years. We have experience producing wire cloth for industries such as coal, landscaping, concrete, gravel & sand, and more. Our line of wire mesh products includes self-cleaning screens, perforated plate, screening accessories, and more. If you have a design in mind call us and will manufacture what...

Since 1885, Phoenix Wire Cloth has been a wire cloth manufacturer of industrial wire cloth, welded wire cloth, wire mesh, stainless steel wire cloth and filter cloth. Phoenix Wire Cloth produces wire cloth for fences as well as safety and security equipment and supplies.

More Wire Cloth Manufacturers

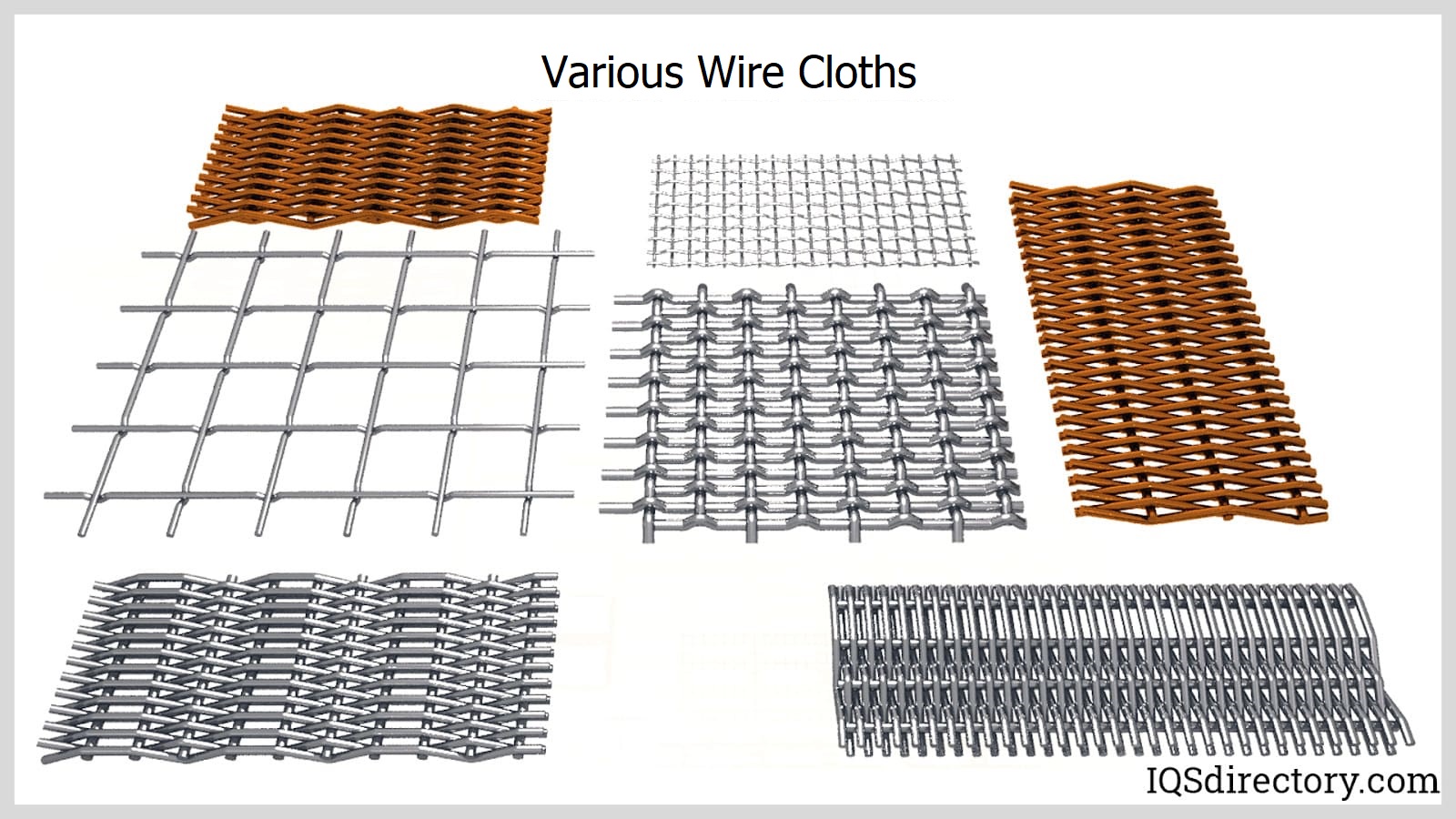

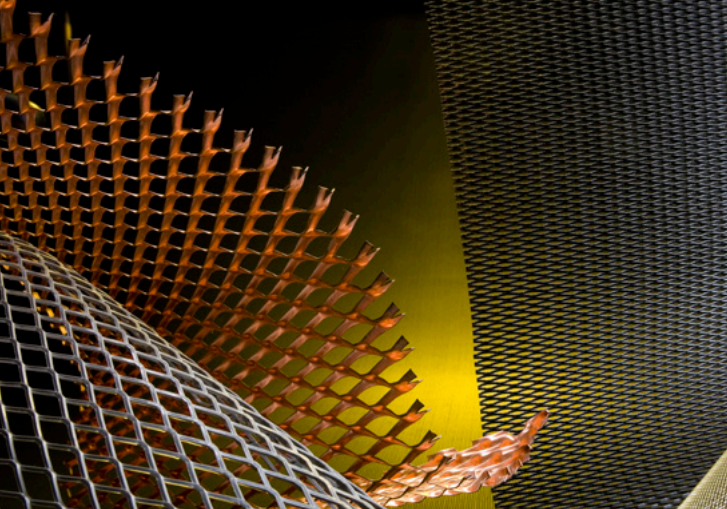

Types of Wire Cloth

Woven and welded wire mesh are the most used in manufacturing. Producing woven wire mesh is more challenging since it calls for precisely positioning the wires in an interlocking pattern and using a weaving loom ram to crimp the wires into place. As a result, the finished wire cloth product is of higher quality and is slightly more expensive. Products made from welded wire mesh are made up of parallel wires that are joined at their points of junction. Welded wire provides additional strength and versatility since they can be easily cut or bent into various shapes without the wires falling apart.

Market-Grade Wire Cloth

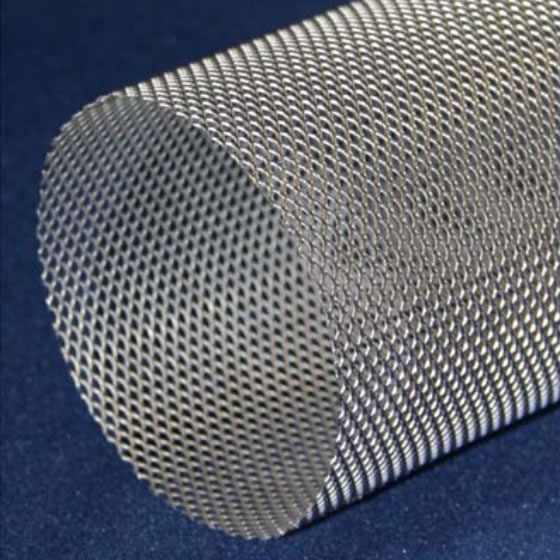

Market-grade is a type of woven wire mesh that comes in various frequently used and diameter wire combinations. Market-grade mesh products with a wide range of apertures per linear inch can be made by wire mesh cloth producers using a variety of metal kinds. Filtration and separation, building, and construction are a few examples of typical wire-grade cloth applications.

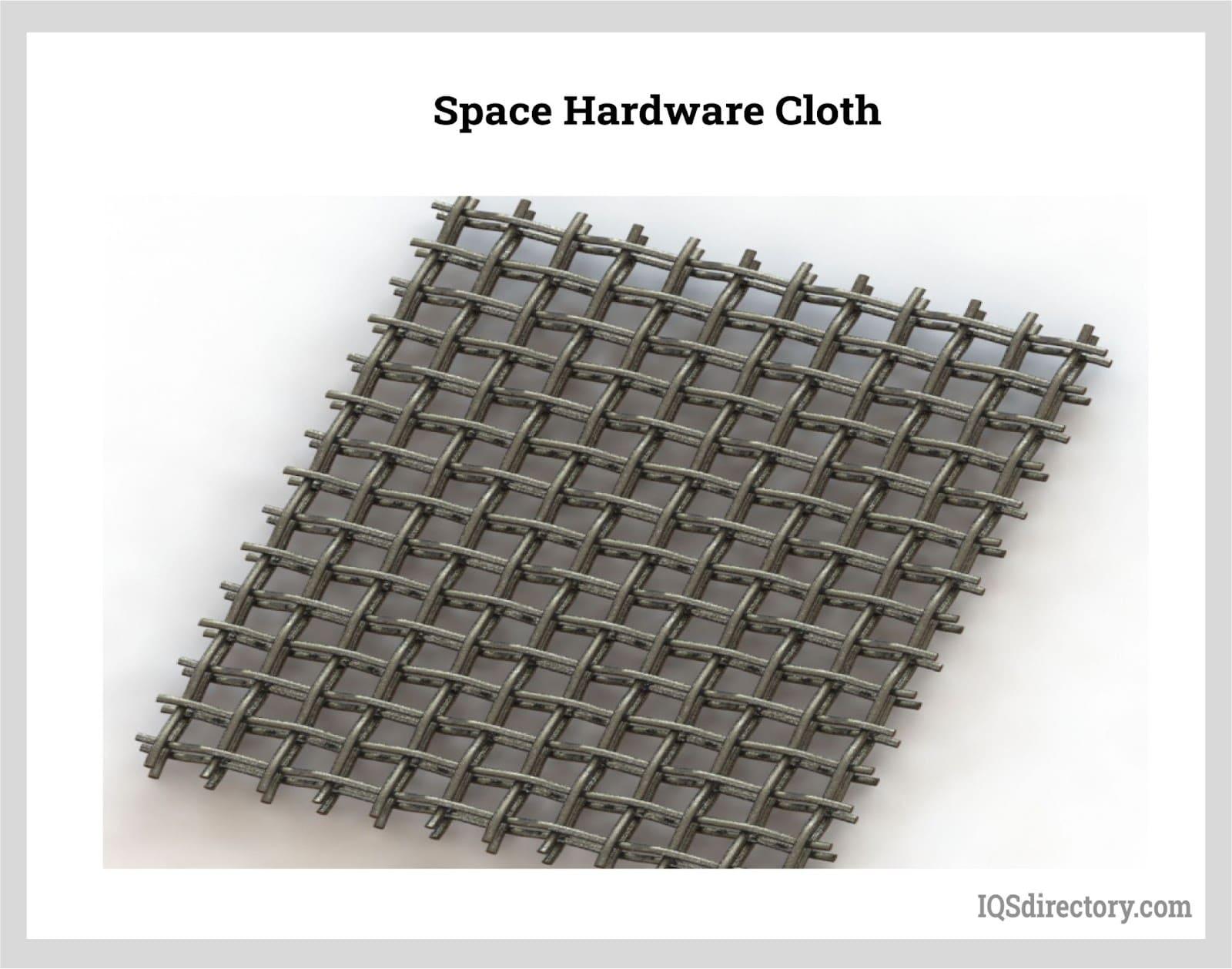

Space Cloth Wire Mesh

Woven and welded wire mesh manufacturing/fabrication techniques are suitable for producing space cloth. The defined gap between wire strands that characterizes space cloth's design and manufacture gives it its name. Space cloth material is available in various open area percentages to satisfy the requirements. There are many different space cloth alternatives available.

Refinery-Grade Wire Mesh

Refinery-grade mesh is made specifically for industrial applications. It can be woven or welded to satisfy the exacting specifications of gas, oil, and other refineries where dependable performance is a must. Pipe fittings, catalyst support grids, and other items are some products that can profit from refinery-grade mesh. In addition, the possibility of plugging is reduced by the stiff design and continuous slot construction of refinery-grade mesh.

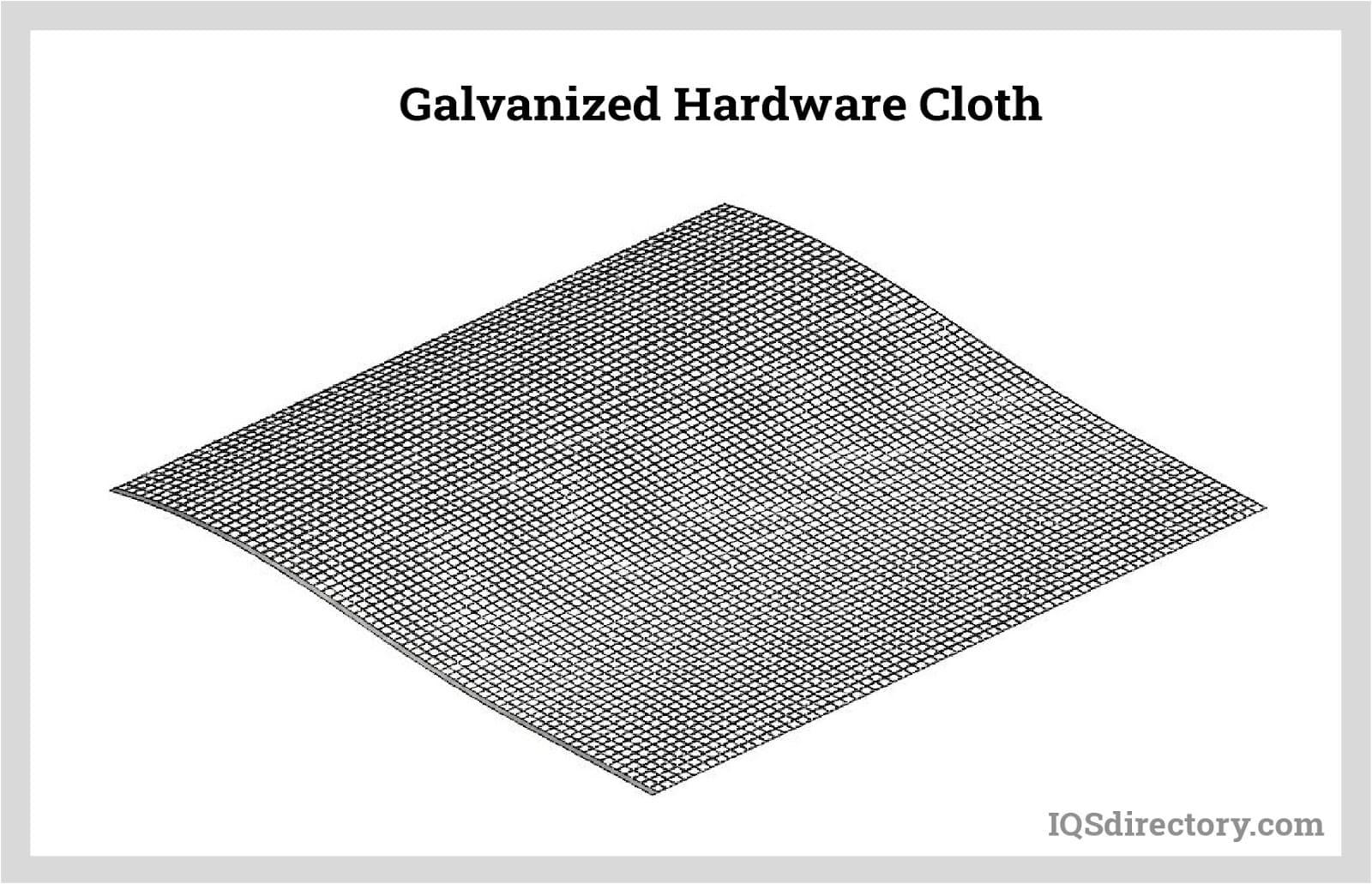

Galvanized Hardware Cloth

A corrosion-resistant zinc coating is applied during the hot-dip galvanization process to create welded or woven galvanized hardware cloth. To reduce damage from exposure to moisture and other elements, galvanized hardware cloth is a fantastic option for outdoor applications. Common uses for this light gauge product include an outdoor fence, building and construction projects, pest control measures, and more.

Mill-Grade Wire Cloth

Market-grade fabric is a heavier version of mill-grade wire cloth. Mill-grade cloth has thinner, lighter wire diameters and less open area. It is typically composed of stainless steel. However, it is also frequently made of aluminum, brass, and copper. The sifting and grinding flour, separating seeds and feed, and other screening procedures using lighter materials are examples of common mill-grade applications.

Wire Filter Cloth

A woven wire mesh product called filter cloth is renowned for its toughness. Strong, heavy warp wire makes filter cloth perfect for demanding screening and filtering applications. It's a great option for slurry and liquid material separation as well.

Bolting Wire Cloth

The thin, smooth, flexible, robust wires in stainless steel bolting wire cloth are precisely woven to form a set of meshes with superior screening properties and quick bolting action. Bolting wire cloth has a thin structure, a flat, smooth surface, and a square weave pattern. For sifting and screening applications, stainless steel is popular because it offers excellent corrosion protection.

Architectural Wire Cloth

For architects and design experts, architectural wire mesh is a good resource. Designers value it for its functionality and aesthetic appeal. In addition, many people employ common, commercial-grade wire in their structures, including schools.

Considerations When Choosing Wire Cloth Products

When selecting wire cloth products, one must also take into account the following factors when choosing between woven and welded wire mesh:

Mesh size: The diameter of the mesh's apertures, which impacts how well it can screen materials that pass through it, is indicated by mesh size. The mesh's diameter might be between a few microns and many inches.

Mesh number: The number of wires contained within a linear inch is known as the mesh count. The mesh apertures will be narrower as the mesh count increases.

Weave type: If one decides to use woven wire cloth, one must choose the right weave type because it will affect the filtering performance. The design of the warp (vertical) and weft (horizontal) wires determines the type of weave. Depending on the application, the warp and weave wires can have similar or different widths.

Mesh: The mesh shows how many apertures there are per lineal inch. Measure the distance from a wire's center to a point one inch away, then count the number of apertures to determine the mesh.

Opening: The measurement of the clear, unobstructed area between parallel wires is called the opening. When this measurement is applied, pre-crimped woven wire known as "space cloth" is utilized.

Choosing the Correct Wire Cloth Manufacturer

To ensure you have the most beneficial outcome when purchasing wire cloth from a wire cloth manufacturer, it is important to compare several companies using our directory of wire cloth manufacturers. Each wire cloth manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each wire cloth business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple wire cloth companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services