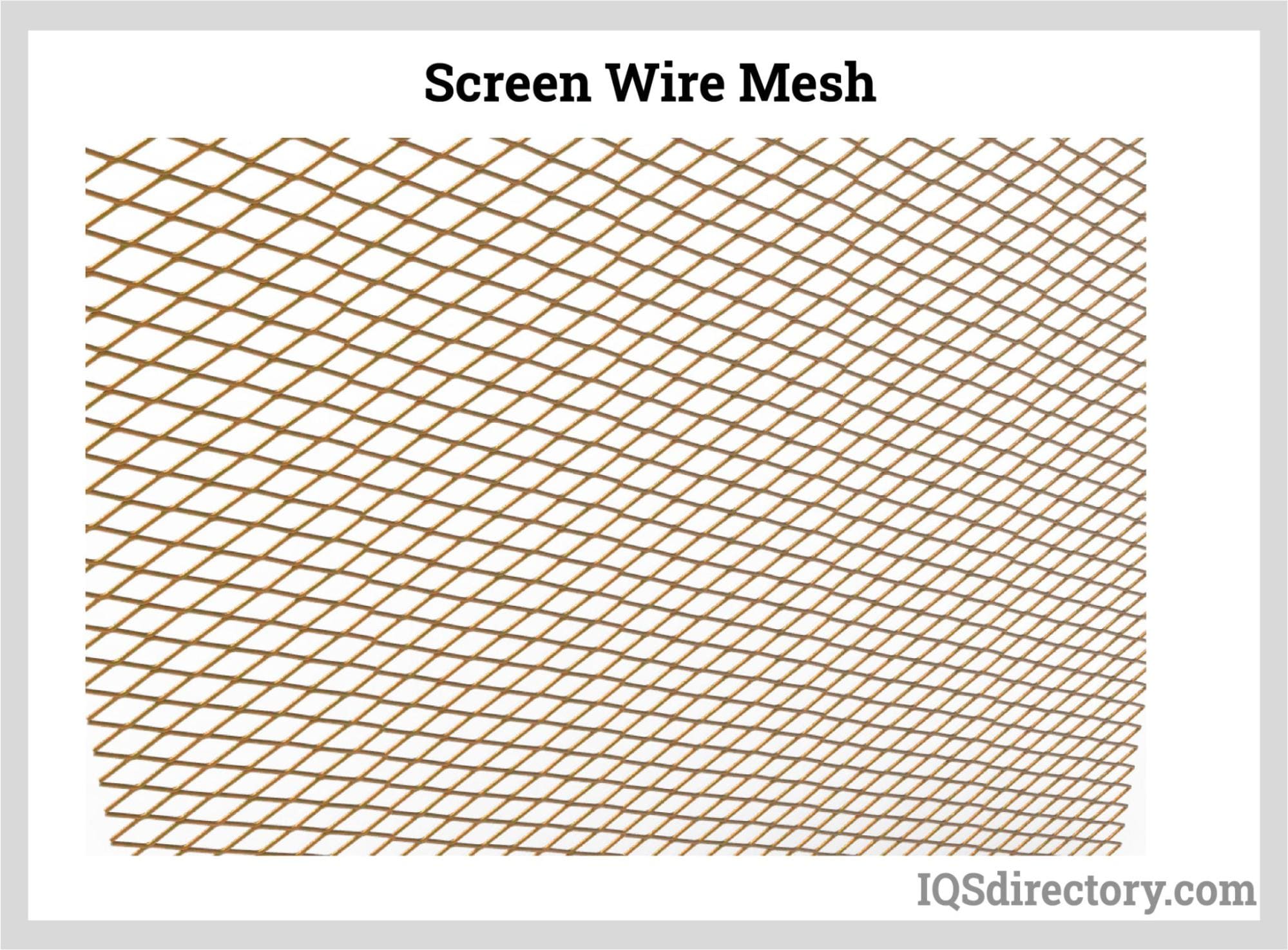

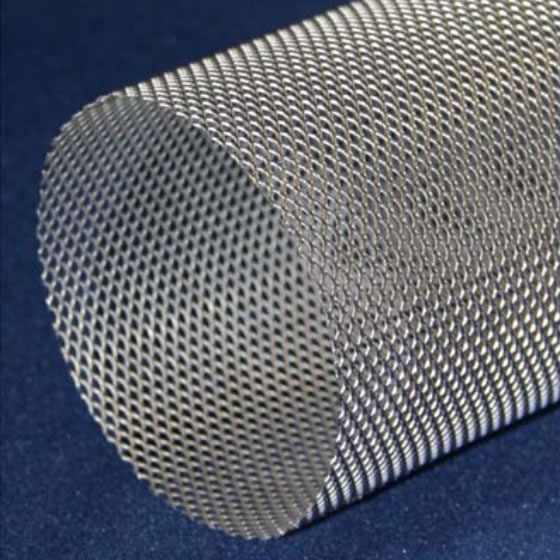

Woven wire cloth with either square or rectangular “working holes” known as screen cloth, or wire mesh screen, It is created on substantial weaving apparatuses called looms. It is produced using a variety of weave patterns and wire diameter and aperture size combinations. The open spaces or distances between the wires of the woven wire fabric in both directions are referred to as “working apertures.” Read More…

We’ve been a leading manufacturer and distributor of wire cloth/mesh for 70 years, sourcing and stocking North America’s largest selection of wire cloth products – over 5000 in our warehouse. We offer processing capabilities such as precision cutting, calendering, heat treating, cleaning and coating and weave domestically most alloys including brass, copper, Hastelloy, Monel and others into ...

Banker Wire is your quality-driven manufacturing partner for woven and welded wire mesh used in architectural and industrial applications. Our manufacturing expertise has been refined for over a century, bringing unmatched customization, quality, and service to our customers. Our products embody our commitment to providing the widest variety of wire cloth at an unbeatable value. Nowhere else will ...

For over 45 years, UWC has supplied quality mesh products for numerous industries with distinct applications. We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles. Our fabrication services comprise shearing, slitting and stamping options. In addition, we produce baskets, trays, cylinders,...

Marco Specialty Steel is a leading-supplier of wire cloth, wire cloth screens and wire mesh. Our warehouse maintains a wide range of wire cloth products in a variety of material grades and styles. We offer wire cloth in full rolls, cut-to-size pieces, slitting, circle cutting, blanking and stamping.

Hoyt Wire Cloth is a family-owned business that has been serving a variety of markets for over 50 years. We have experience producing wire cloth for industries such as coal, landscaping, concrete, gravel & sand, and more. Our line of wire mesh products includes self-cleaning screens, perforated plate, screening accessories, and more. If you have a design in mind call us and will manufacture what...

Since 1885, Phoenix Wire Cloth has been a wire cloth manufacturer of industrial wire cloth, welded wire cloth, wire mesh, stainless steel wire cloth and filter cloth. Phoenix Wire Cloth produces wire cloth for fences as well as safety and security equipment and supplies.

More Screen Cloth Manufacturers

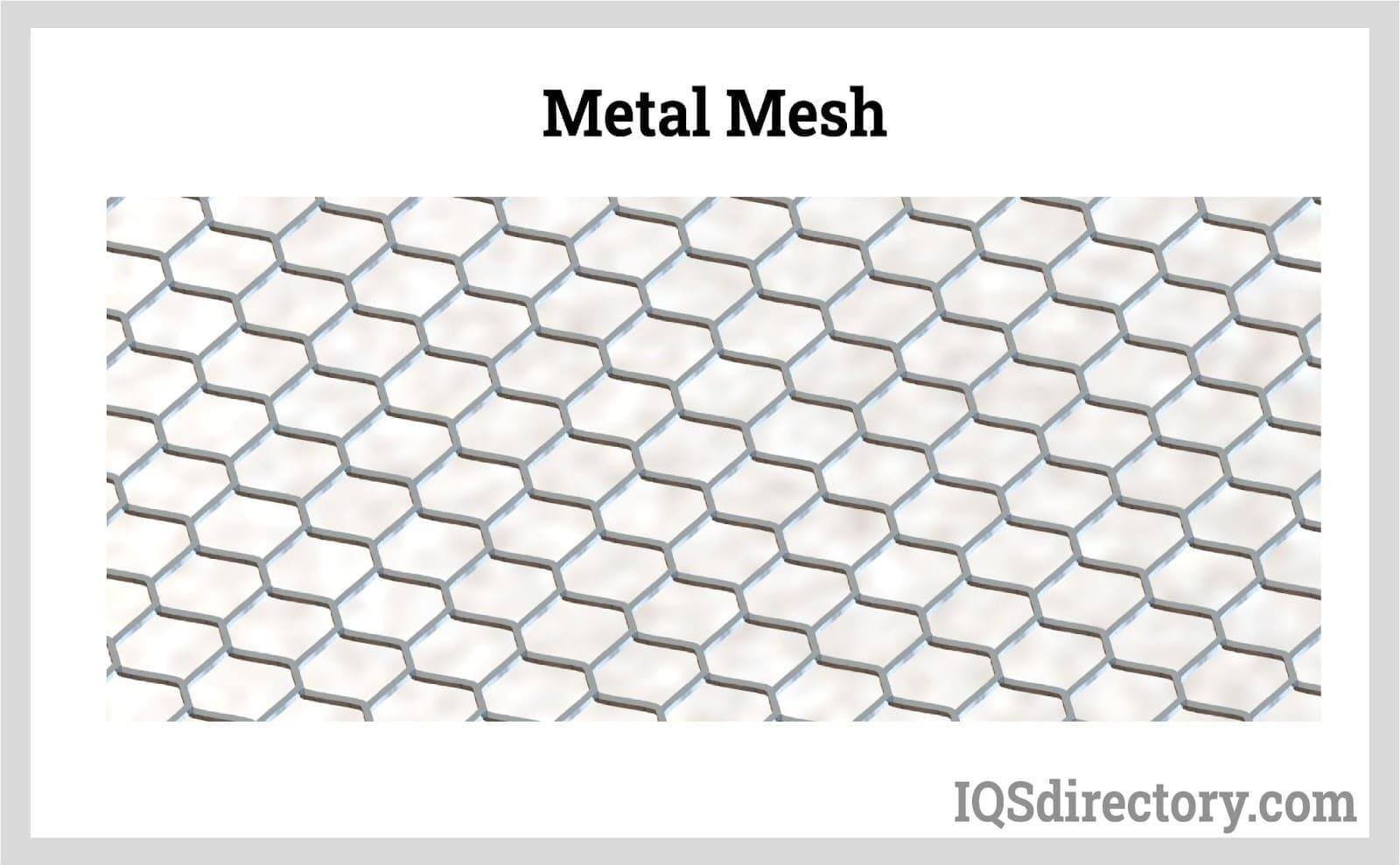

The matrix of wires that are placed at 90°angles is what makes wire mesh unique. Almost any type of metal can create wire-cloth products, including stainless steel, copper, aluminum, nickel, molybdenum, etc. This material is widely used in numerous industrial fields, including chemical processing, medicines, water purification, refrigeration, metallurgy, gas separation, the automobile industry, and aerospace. Shaker or vibrating screens for sifting and sizing, baskets, liners, and separator rings are a few examples of screens made with screen cloth.

Applications of Screen Cloth Wire Mesh

- Filtering and separation equipment

- Used in systems for cooling buildings

- In air purifiers

- Filters for dishwashers

- Noise reduction devices

- Filters for oil

- Detection of gas services

- Hydraulic mechanisms

- Metering technology

- Keeping flies and other flying insects from entering homes

Advantages of Screen Cloth Wire Mesh

- They provide a great range of filtration, with a nominal high open area/flow rates and apertures as small as 1 micron and as large as 6 inches.

- Uniform surface with no burrs, acute angles, or sharp edges on the screening surface

- High tolerance for temperature (variable according to metal selected)

- Suitable for producing rigid concave/convex structures and useable under high pressure

- Control of corrosion, acidity, and chemical resistance utilizing various metals

- Special aperture needs can be satisfied without incurring expensive tooling expenses.

- high resiliency

- The weaving method is self-supporting, using no punching or piercing procedures, and is ideal as a support for less rigid media.

- It is possible to screen products more freely.

Types of Screen Cloth Wire Mesh

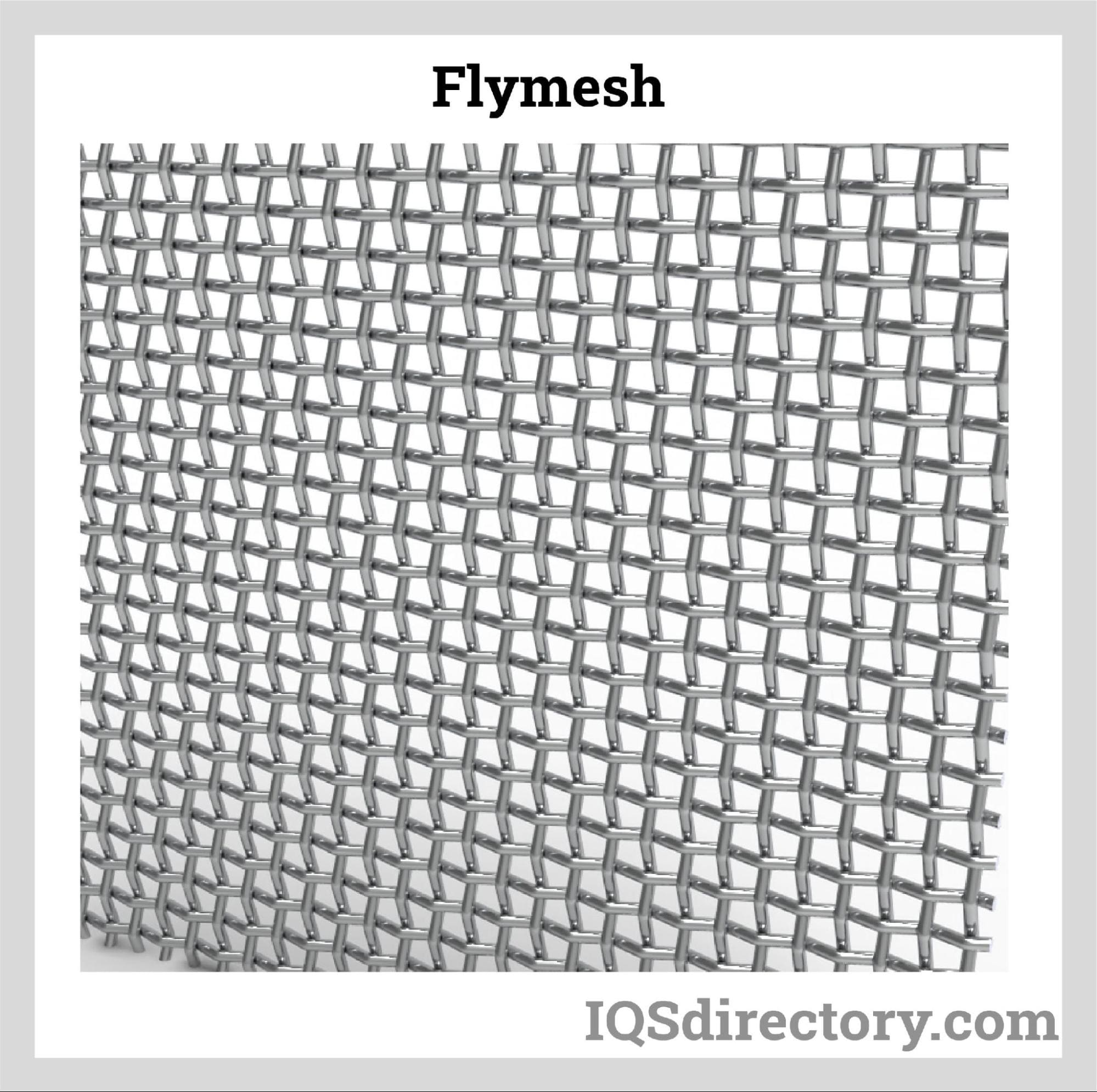

Fly Mesh

A window screen is made to fit over a window opening and is sometimes referred to as an insect screen, bug screen, fly screen, flywire, wire mesh, or window net. Typically, it is a stretched mesh supported by a wood or metal frame constructed of metal, fiberglass, plastic wire, or other types of plastic. For example, the basic mesh for a premium aluminum insect screen comprises woven fiberglass yarn covered in PVC to make it waterproof, rustproof, non-combustible, stain-resistant, and simple to clean.

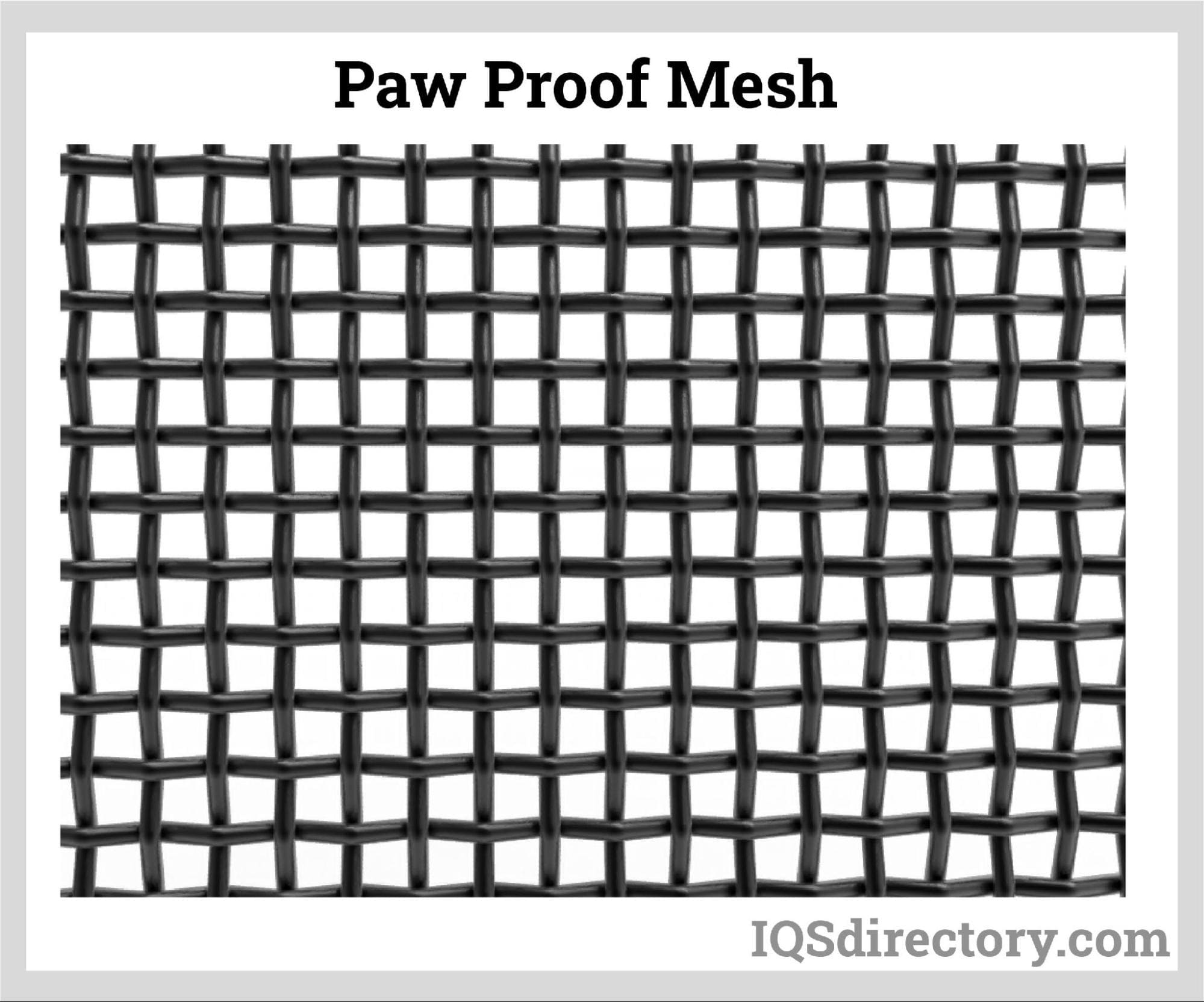

Pet Screen Mesh

Pet screen mesh comprises a flexible fiberglass mesh, making it tougher and more durable than regular nylon mesh. Since cats love to scratch at flyscreens and flyscreen doors, this mesh is perfect for households with pets inside or nearby. In addition, this fiberglass mesh with PVC covering is soft, flexible, and 20 times stronger than ordinary mesh; it is designed not to rust, rot or corrode. This mesh can stop any claws, teeth, and critters up to no good. As a result, this material is ideal with pets, kids, and high-traffic areas. This mesh is also sturdy enough to survive torrential downpours and other severe weather conditions.

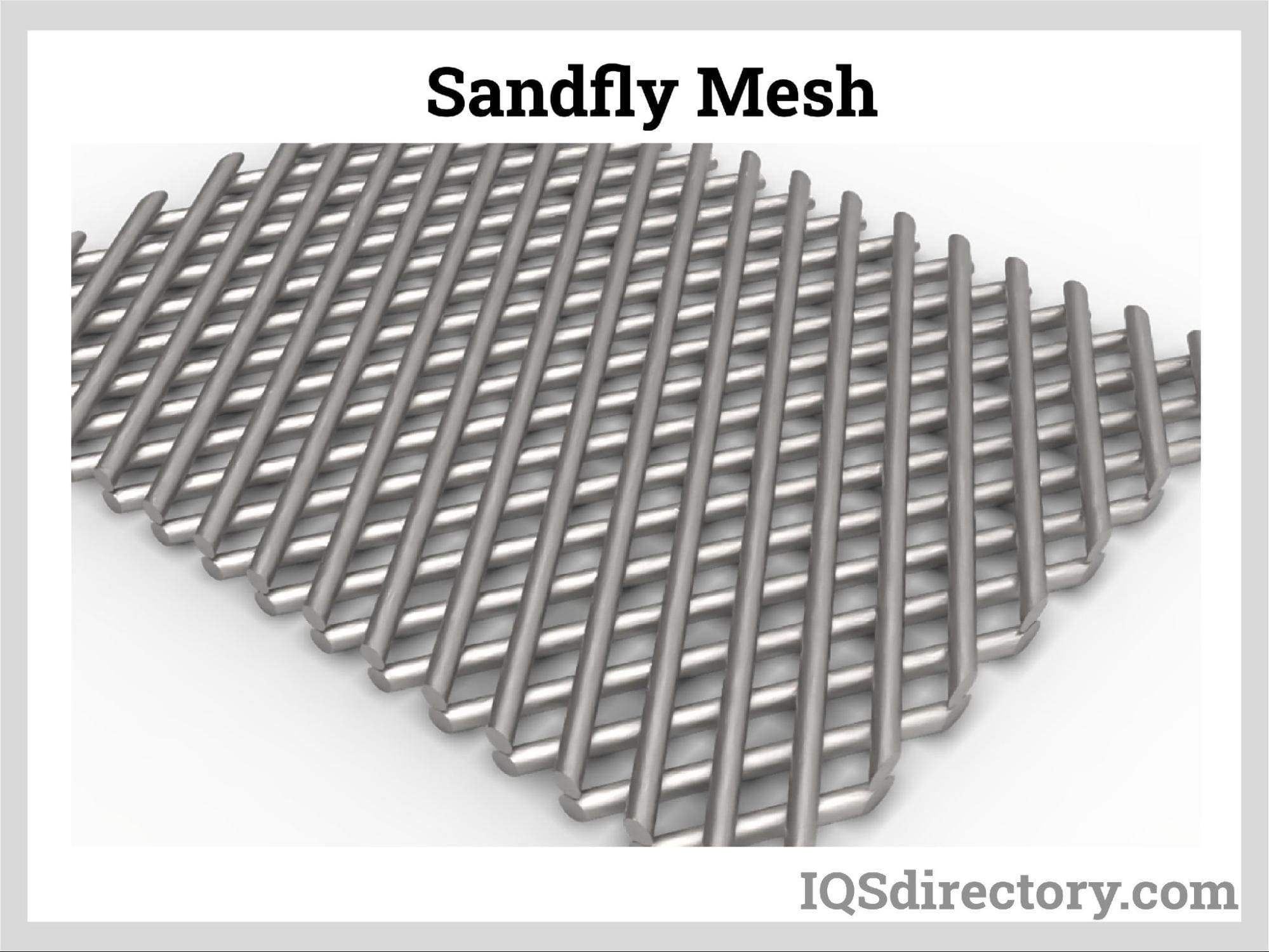

Sandfly Mesh

Small biting insects like sandflies and phlebotomes are prevented from biting by a thin sandfly mesh which contains 35 holes per square cm. This fiberglass mesh with a tiny opening to keep out mosquitoes, fruit flies, midges (also known as sandflies), and other tiny insects. This mesh is carefully woven from the best materials to provide consistency, dependability, and long-lasting performance, and is ideal for tropical areas to screen windows and doors from tiny insects. Mini-weave versions are flexible and bendable for simple installation, UV stabilized, and reduce glare. This version contains 20 x 20 strands per inch.

One Way Vision Mesh

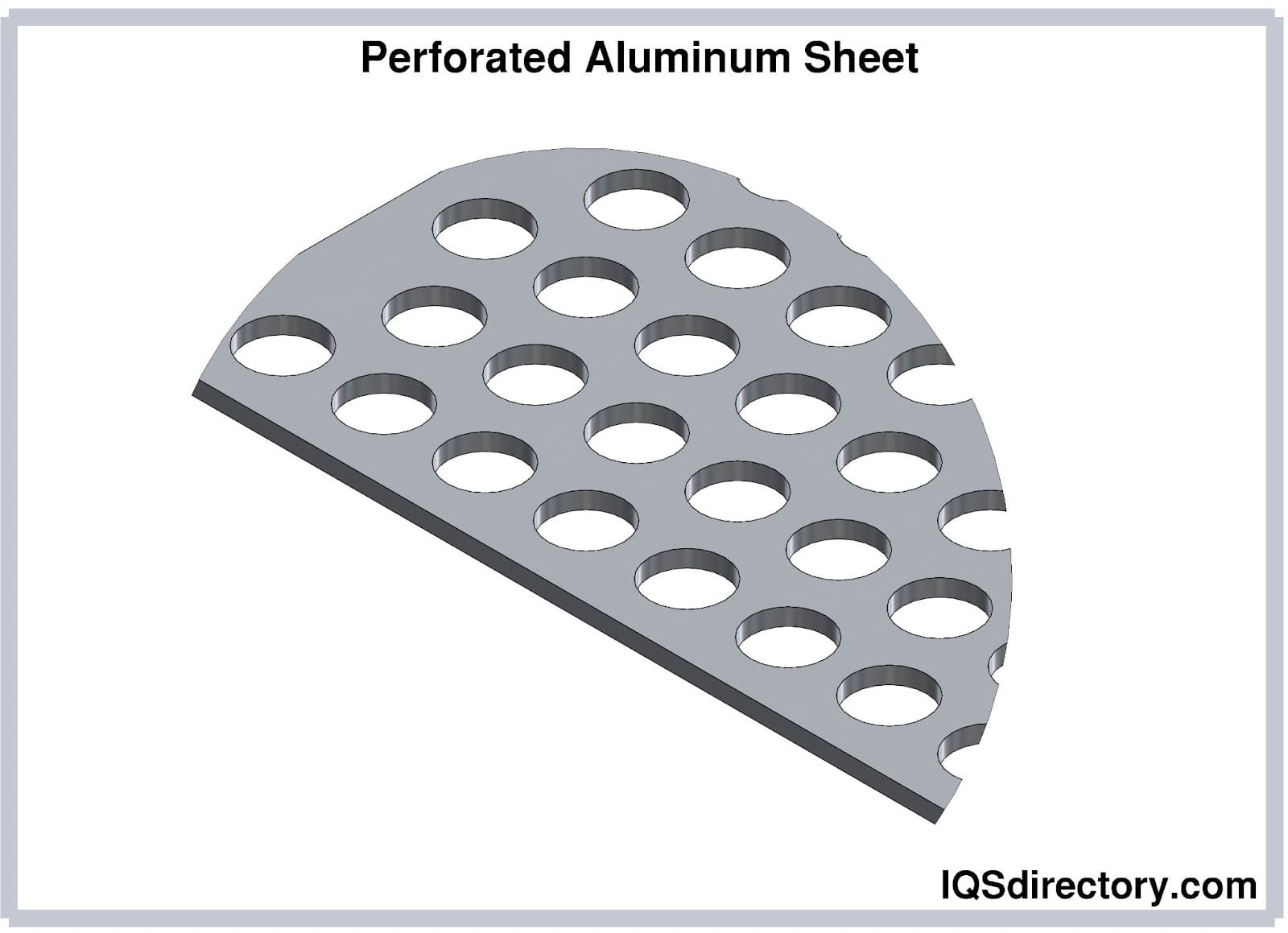

A highly corrosion-resistant, expanded aluminum sheet creates a one way vision mesh. The one way vision mesh enables the occupant to view outside while preventing visitors from seeing them.

The Characteristics of One Way Vision Mesh

- Aluminum is the material.

- Square or diamond-shaped holes

- The surface treatments are PVC coating, galvanizing, epoxy resin, anodizing, and powder coating.

- The available hues are black, white, silver, yellow, green, or red.

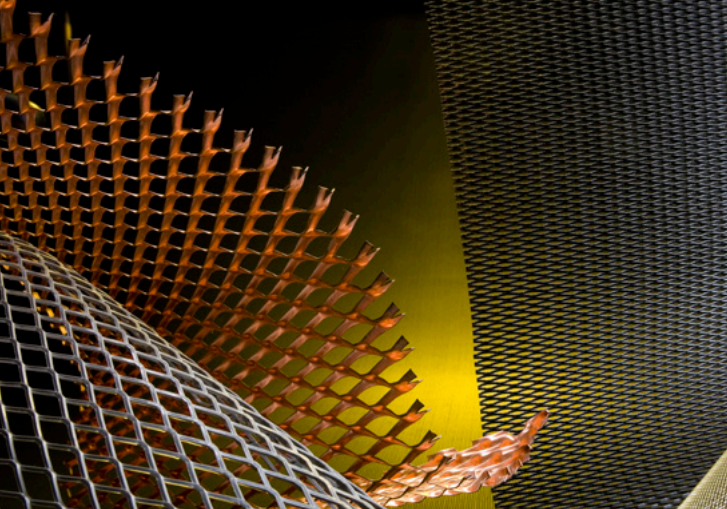

Diamond Pattern Mesh

Diamond pattern mesh is made from a welded aluminum extrusion that offers moderate security and protection against house invasions. It is available for windows and glass doors (small, jeweler, and standard). With clean and unrestricted exterior views, diamond pattern mesh provides the comfort of fresh air flowing through as a screening material.

This material provides the best option for point of entry home security. In addition, the grille is welded to the frame at regular intervals for enhanced durability. The result is a safety door that prevents unwanted visitors away.

Choosing the Proper Screen Cloth Manufacturer

To ensure you have the most beneficial outcome when purchasing screen cloth from a screen cloth manufacturer, it is important to compare several companies using our directory of screen cloth manufacturers. Each screen cloth manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information. Review each screen cloth business using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple screen cloth companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services