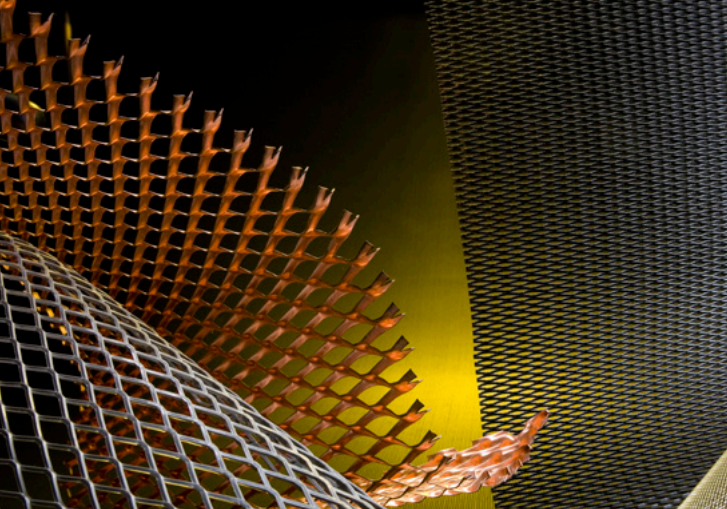

Stainless steel mesh is a form of galvanized wire mesh. However, because the material has unique qualities and benefits, it frequently receives its own category. Unique in its use, galvanized wire mesh is made of steel that has a protective zinc coating applied to it. Typically, it is used on steel or iron products that are particularly prone to oxidation (rust is iron oxide). Tin, copper, and alloys created from these metals are some examples of other metals that can be galvanized. Doing so makes it easier to fit the protective covering into confined areas where wires intersect. Additional finishes, such as acrylic paints or a thin coating of less reactive chromium or aluminum, are occasionally added. In addition to preventing corrosion, the zinc, and any extra, coatings strengthen the metal screens overall. Read More…

We’ve been a leading manufacturer and distributor of wire cloth/mesh for 70 years, sourcing and stocking North America’s largest selection of wire cloth products – over 5000 in our warehouse. We offer processing capabilities such as precision cutting, calendering, heat treating, cleaning and coating and weave domestically most alloys including brass, copper, Hastelloy, Monel and others into ...

Banker Wire is your quality-driven manufacturing partner for woven and welded wire mesh used in architectural and industrial applications. Our manufacturing expertise has been refined for over a century, bringing unmatched customization, quality, and service to our customers. Our products embody our commitment to providing the widest variety of wire cloth at an unbeatable value. Nowhere else will ...

For over 45 years, UWC has supplied quality mesh products for numerous industries with distinct applications. We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles. Our fabrication services comprise shearing, slitting and stamping options. In addition, we produce baskets, trays, cylinders,...

Marco Specialty Steel is a leading-supplier of wire cloth, wire cloth screens and wire mesh. Our warehouse maintains a wide range of wire cloth products in a variety of material grades and styles. We offer wire cloth in full rolls, cut-to-size pieces, slitting, circle cutting, blanking and stamping.

Hoyt Wire Cloth is a family-owned business that has been serving a variety of markets for over 50 years. We have experience producing wire cloth for industries such as coal, landscaping, concrete, gravel & sand, and more. Our line of wire mesh products includes self-cleaning screens, perforated plate, screening accessories, and more. If you have a design in mind call us and will manufacture what...

Since 1885, Phoenix Wire Cloth has been a wire cloth manufacturer of industrial wire cloth, welded wire cloth, wire mesh, stainless steel wire cloth and filter cloth. Phoenix Wire Cloth produces wire cloth for fences as well as safety and security equipment and supplies.

More Galvanized Wire Mesh Manufacturers

Today, galvanized wire mesh is used in countless applications. As a result of galvanization, customers receive better value from products with longer lifespans and less upkeep.

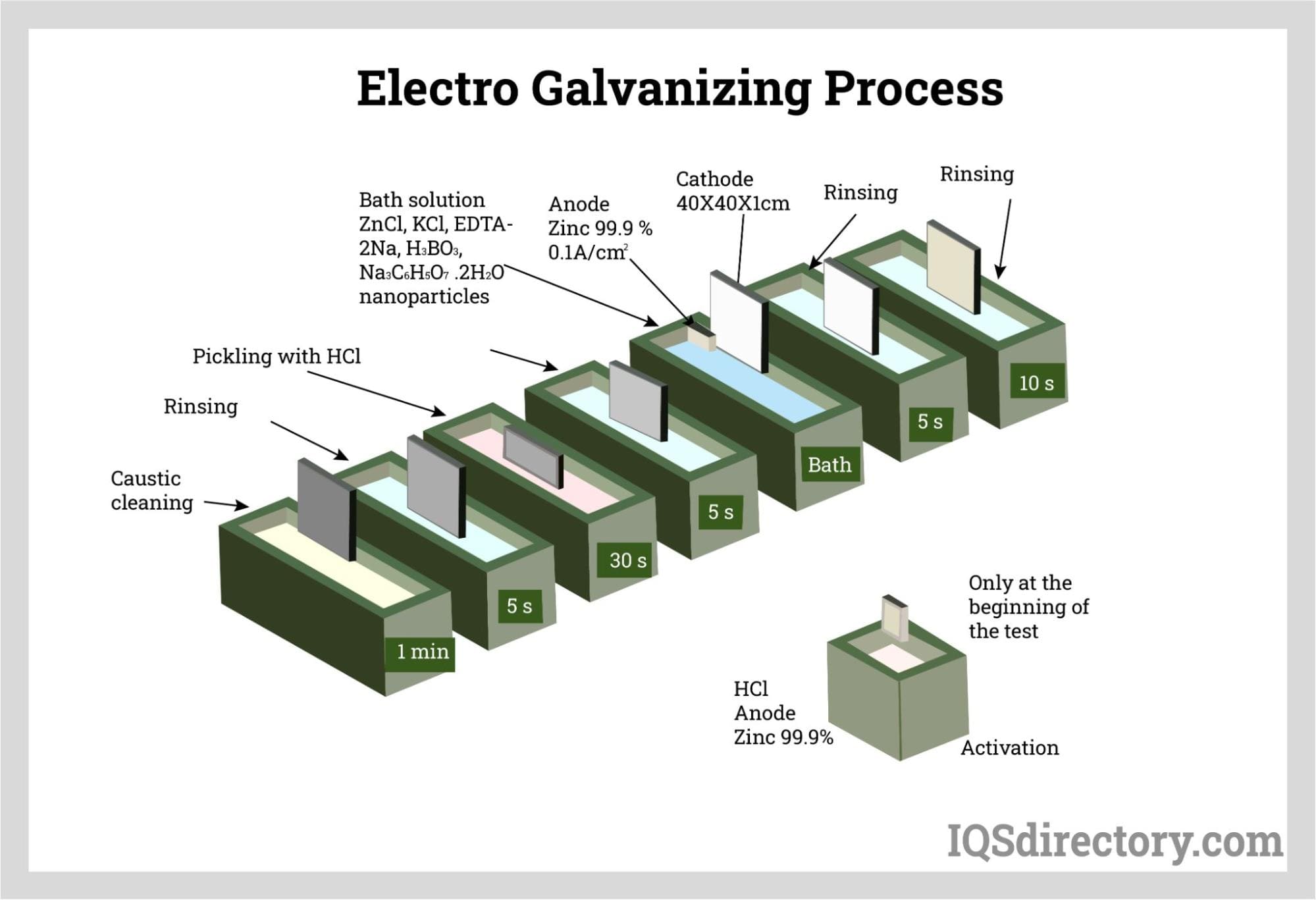

Methods for Creating Galvanized Wire Mesh

The strength and resilience of galvanized wire mesh are due to a thick, substantial zinc outer layer. There are two methods for coating: hot- dipping and electro-galvanizing. Hot-dipping, or putting the wire mesh through a bath of molten zinc-based alloys, is the typical procedure for galvanizing metals. Electro-galvanizing, in which the zinc alloy and steel mesh are joined by opposing electrical charges, can be utilized for protective coatings that are lower in weight. Below is a description of each process.

Hot-Dipping

Steel and zinc are joined together chemically and physically during hot-dip galvanizing, or hot-dipping. The process is explained below.

- To remove dirt, debris, oil, and other leftovers, the stainless steel is washed using a sodium hydroxide solution.

- Any mill scale, rust, pollutants, and other surface impurities are cleaned using an acidic solution.

- To stop oxidation, the surface is coated with a cleaning substance called a "flux" that contains zinc ammonium chloride. This mixture stays on the steel because it makes the zinc adhere.

- The stainless steel is then submerged in molten zinc (liquified at an extremely high temperature).

- Once the steel reaches the same temperature as the hot zinc, it is left in the vat.

- The stainless steel is swiftly cooled in a special tank after being taken from the vat.

Electro-Galvanizing

As opposed to hot-dipping, electro-galvanizing (also known as electrolytic-galvanizing) is a cold procedure. An organic solvent is made from zinc particles which is subsequently applied to the steel’s surface. The chemicals react with one another, to create a zinc-steel alloy. The zinc stays on the metal after the solvent evaporates. In comparison to hot-dipping, electro-galvanizing typically leaves a thinner zinc coating.

Spangles

Larger steel objects that have been galvanized frequently have a visible zinc coating. This visible layer has a crystallized, snowflake-like appearance and is referred to as a "spangle." Wire mesh screens can contain crystallites, but they are typically too small to notice.

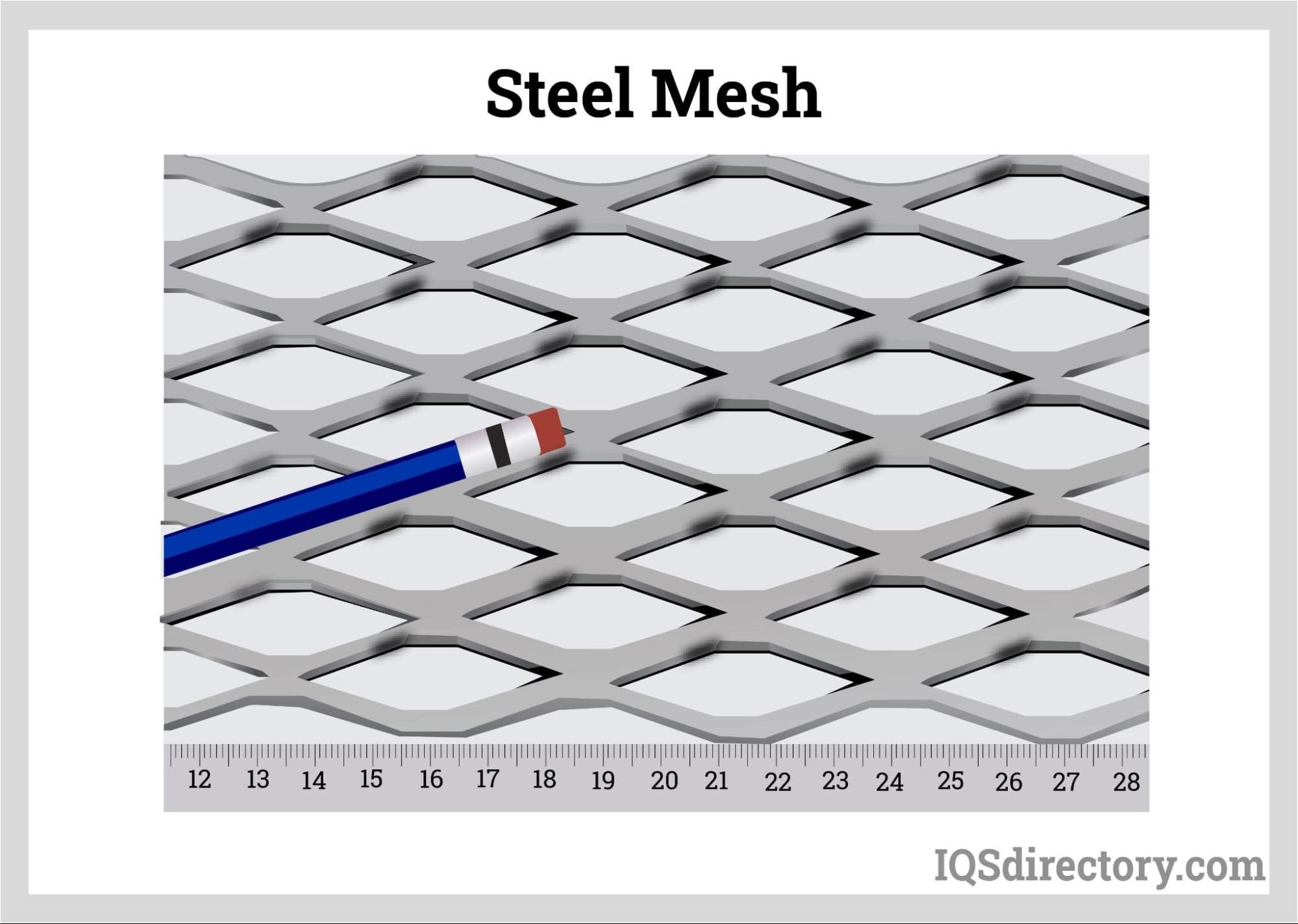

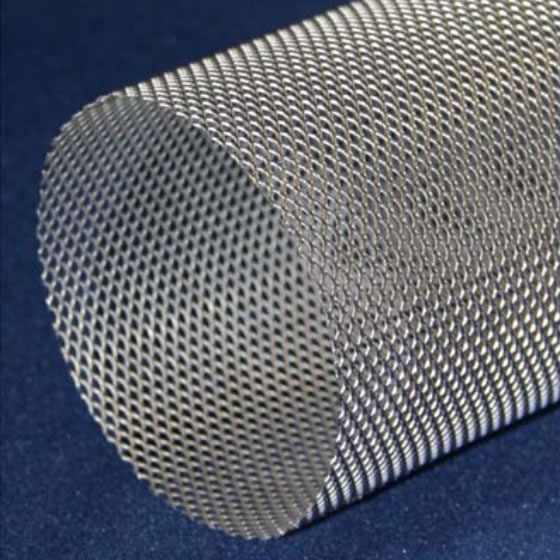

Meshing Size

Given mesh parameters may vary by maker and product type. One way to identify a certain mesh is by the opening size, like 1-½” mesh. However, even typical chicken wire from the same manufacturer might have openings ranging in size. Mesh size is better expressed as the number of spaces within a square inch because the opening between wires will vary based on the product and wire diameter. This range in opening size is done to meet the demands of various clients. For example, the openings in fencing might be 2x4, 2x2, or 4. For example, a typical window screen will have a mesh size of about 18x16 and be designed to keep out insects as small as gnats. Accordingly, there are 16 apertures in a 1-inch vertical measurement and 18 openings in a 1-inch horizontal measurement. Numerous manufacturers across the sector may standardize sizes and apertures. For example, a product requiring No. 2 mesh will have a 0.42” hole with 0.08” diameter wire. This mesh is also known as each area having 70.5 percent unoccupied space.

Benefits of Galvanized Wire Mesh

A more affordable alternative to panels or board fences is galvanized wire mesh. It comes in rolls that can be split into desired lengths or sizes, with the leftovers being rerolled for simple storage. Most meshes can be easily cut to fit any needed dimensions using wire cutters or power-cutting equipment like grinding wheels. Various fasteners, such as nails, screws, clips, and smaller bits of wire, can hold them in place. Compared to other mesh materials, galvanized steel mesh is much stronger and more resilient. Compared to corrodible materials that need to be changed regularly, galvanized wire mesh costs less in the long run. It can be bent back into shape and offers increased resistance to impacts thanks to its flexibility. Greater security and tranquillity are also provided. Mesh is available in so many variations that it can support the aesthetics of other property components. Large rolls can be bought to provide consistency across a property or large-scale project. It can be painted, bent, and sculpted to fit various areas, angles, and curves.

Industrial Applications of Galvanized Wire Mesh

The material plays a significant role in numerous industrial applications due to its exceptional durability and resistance to corrosion. Uses for galvanized stainless steel screens include:

- farming and agriculture

- archaeology

- safety enclosures and fencing

- landscaping, gardening, and greenhouses

- soffit screens, gutter guards, and foundation vents

- applications for HVAC

- substance screening

- pest management

- retention walls

- insulation, drywall, infill panels, roofing, and ceilings

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services