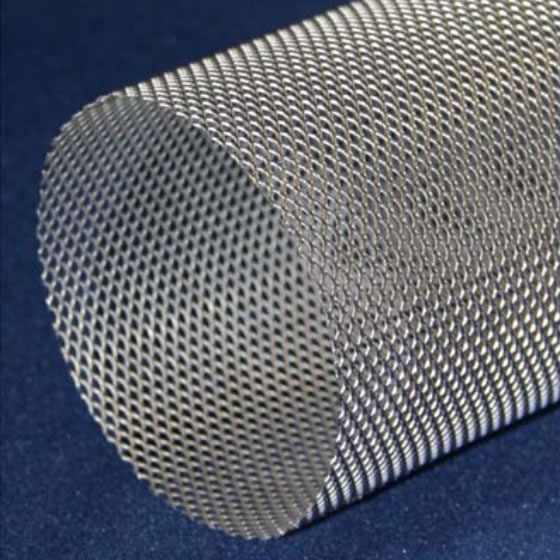

Steel mesh consists of a web-like structure from welded alloyed steel lengths joined together to form a barrier or net. In addition, it is woven into a criss-cross pattern that is frequently very small. The mesh is durable and can withstand a variety of situations. It comes in a range of shapes and sizes. As a result, there are numerous applications for the wire mesh material known as steel mesh. Numerous industries employ this kind of mesh because it has great resistance to corrosion. It is extensively employed in the transportation, horticulture, industrial, agricultural, and food procurement industries. Read More…

We’ve been a leading manufacturer and distributor of wire cloth/mesh for 70 years, sourcing and stocking North America’s largest selection of wire cloth products – over 5000 in our warehouse. We offer processing capabilities such as precision cutting, calendering, heat treating, cleaning and coating and weave domestically most alloys including brass, copper, Hastelloy, Monel and others into ...

Banker Wire is your quality-driven manufacturing partner for woven and welded wire mesh used in architectural and industrial applications. Our manufacturing expertise has been refined for over a century, bringing unmatched customization, quality, and service to our customers. Our products embody our commitment to providing the widest variety of wire cloth at an unbeatable value. Nowhere else will ...

For over 45 years, UWC has supplied quality mesh products for numerous industries with distinct applications. We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles. Our fabrication services comprise shearing, slitting and stamping options. In addition, we produce baskets, trays, cylinders,...

Marco Specialty Steel is a leading-supplier of wire cloth, wire cloth screens and wire mesh. Our warehouse maintains a wide range of wire cloth products in a variety of material grades and styles. We offer wire cloth in full rolls, cut-to-size pieces, slitting, circle cutting, blanking and stamping.

Hoyt Wire Cloth is a family-owned business that has been serving a variety of markets for over 50 years. We have experience producing wire cloth for industries such as coal, landscaping, concrete, gravel & sand, and more. Our line of wire mesh products includes self-cleaning screens, perforated plate, screening accessories, and more. If you have a design in mind call us and will manufacture what...

Since 1885, Phoenix Wire Cloth has been a wire cloth manufacturer of industrial wire cloth, welded wire cloth, wire mesh, stainless steel wire cloth and filter cloth. Phoenix Wire Cloth produces wire cloth for fences as well as safety and security equipment and supplies.

More Steel Mesh Manufacturers

Types of Steel Mesh

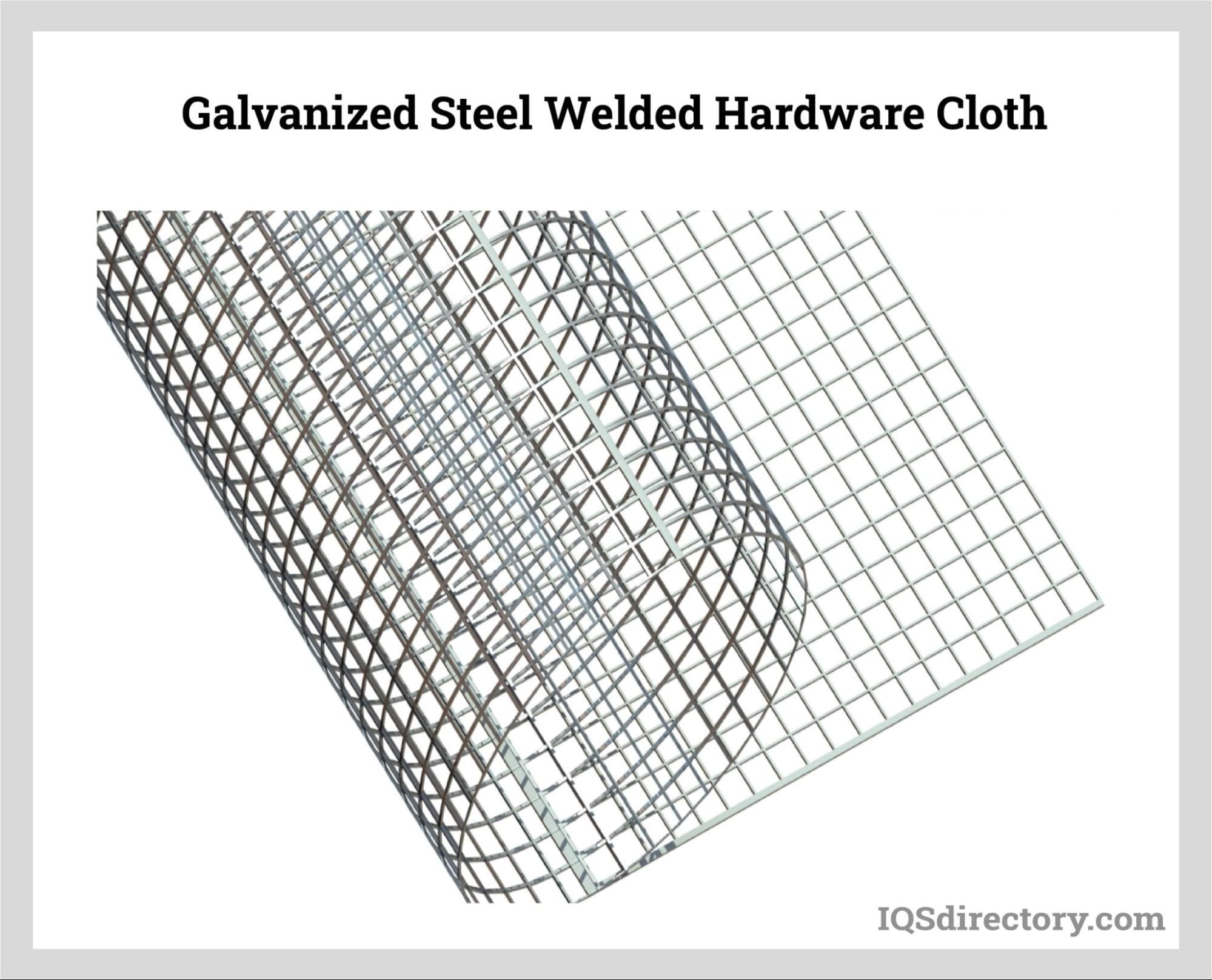

GBW - Galvanized Before Welded

Galvanized wire strands are used to create the GBW fence and mesh. Galvanized before welded mesh is made from wire coated with zinc and then woven into a fabric. Any gauge of wire can be utilized. After being pulled down to its ultimate diameter, the wire is coated with zinc. The wires are subsequently joined by welding or weaving. This process changes the wire at the welded connection where the wires cross as the zinc's protective coating is burned off at these areas during the welding process.

A clean, even coating is applied to the wire’s entire surface using multiple wiping stations, resulting in flexible joints and simple installation.

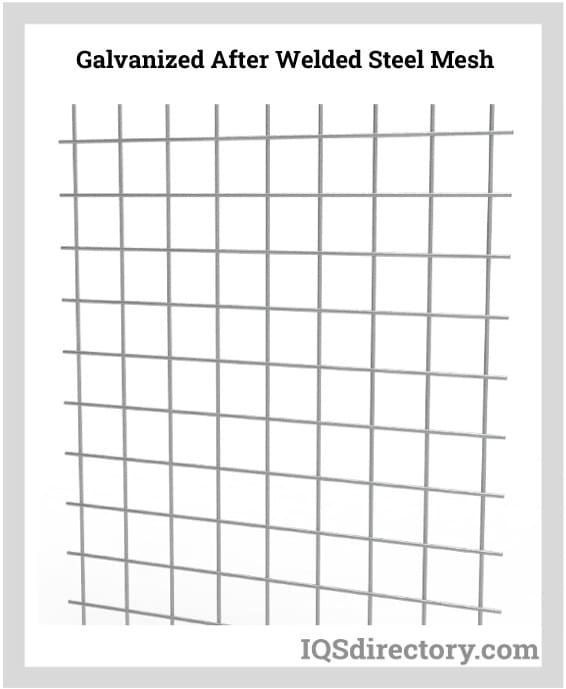

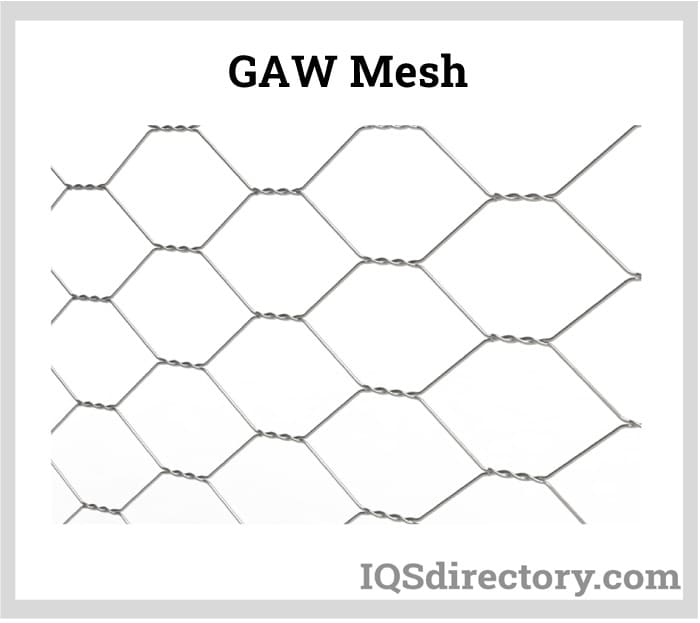

Galvanized After Welded

Galvanized after welded (GAW) wire is created by soaking previously welded mesh into a tub of molten zinc once the wires have been knitted together. As a result, the entire mesh or fence, including the welding point, is thoroughly sealed and protected against rust and corrosion.

A wire mesh galvanized after welding will persist for many years. The thick galvanizing completely encapsulates the wires and shields them from rust and corrosion. Hexagonal netting and small mesh hardware cloth fall under this category's typical items. These meshes and fences are helpful for bird pens and enclosures, as problem wildlife barriers, crayfish and crab traps, and other applications where rust avoidance and long life are sought.

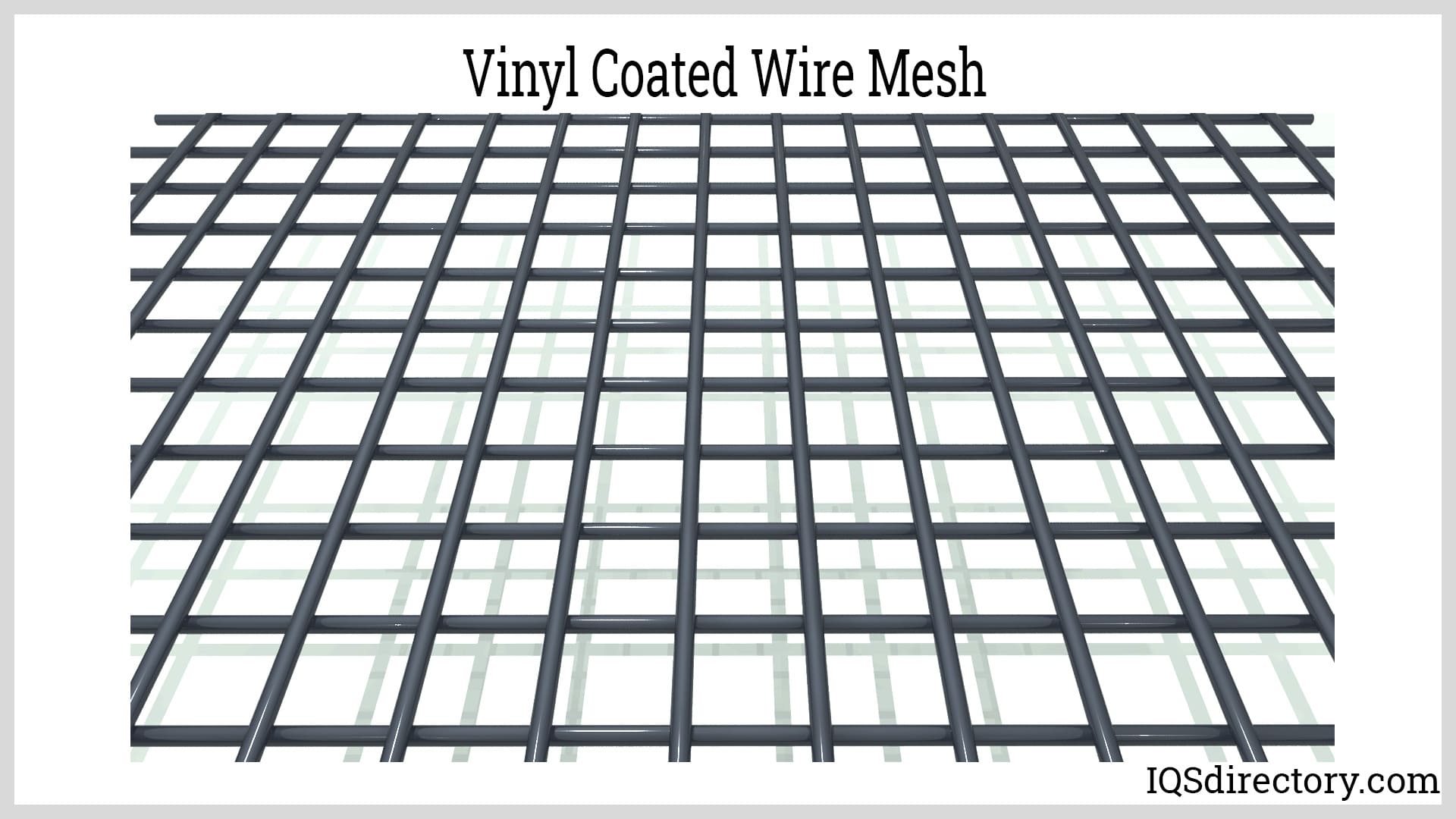

Vinyl Coated Welded and Woven

A vinyl coating is "bonded" to a heated, well-cleaned wire mesh through a precise, specialized procedure to produce this mesh form. A strong, smooth, long-lasting coating without pinholes or thin patches is produced by this unique method. Here, the wire and vinyl coating unite as one.

Chicken wire is a commonly known form of vinyl coated (VC) fencing. It consists of a 1" hexagonal woven wire mesh and has a 20 gauge core wire. There are numerous advantages to this form of steel mesh. We examine these benefits below.

Meshes with Vinyl Coatings are more Resilient

- The galvanized wire beneath is sealed by the vinyl coating, which provides additional rust protection.

- Compared to galvanized wire, a coated wire will survive much longer.

Fences with Vinyl Coating Look Nicer

- An otherwise plain galvanized mesh may receive numerous colors available from the vinyl coating.

- A wire fence with vinyl coating will enhance a property.

- Black is nearly undetectable from a distance and won't interfere with the view.

Wire Covered in Vinyl is Safer

- Wires are cushioned by vinyl.

- The top and bottom of the fence are further protected and sealed by vinyl, as are any areas with sharp edges.

- The fence presents a lesser danger of injury, making it safer for animals and people.

Fencing with a Vinyl Coating is Cost-Effective

- Utilizing a welded or woven fence with a vinyl coating lessens the replacement frequency.

- The less frequent need for repairs and replacement of this material will result in greater labor and material savings, offsetting the higher initial cost.

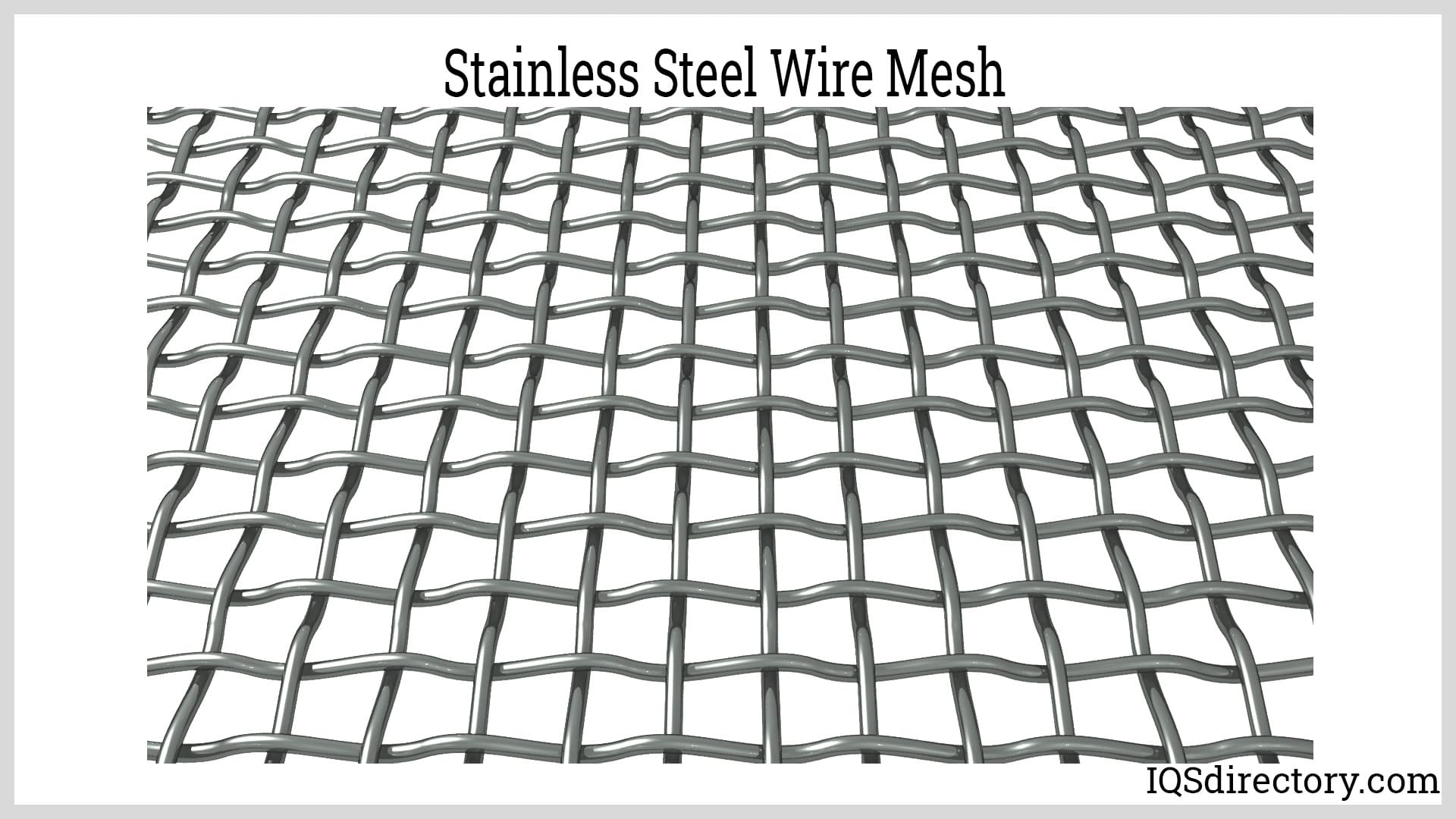

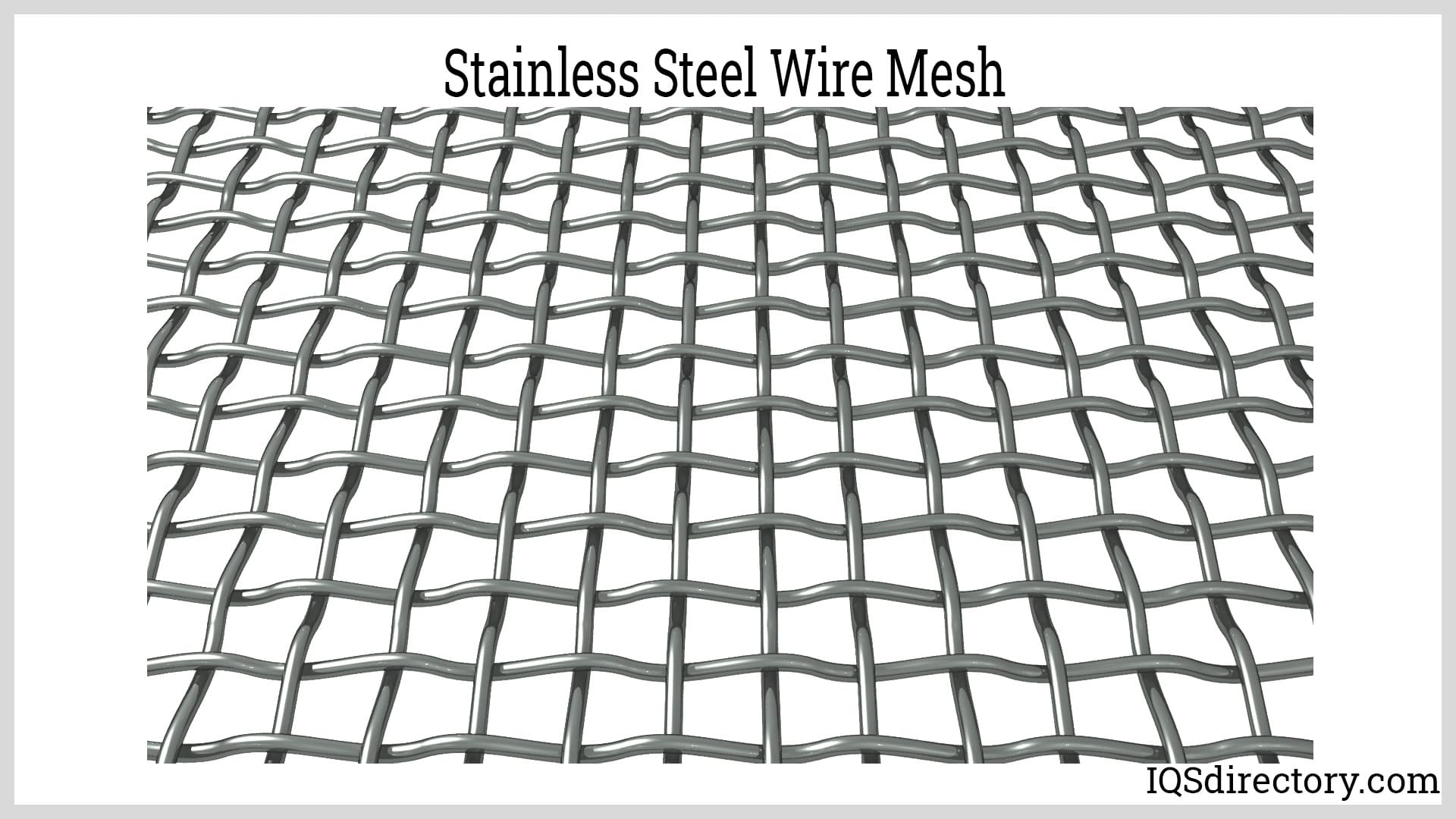

Stainless Steel Mesh

A stainless-steel mesh is a web-like structure made of welded lengths of alloyed steel joined together. Because of its strong corrosion resistance, this kind of mesh is popular across various sectors. Stainless steel is a steel alloy with good formability, drawing, and machining properties. As a result, it's a well-liked material for several fabrications, including metal sheeting and wire mesh items.

Every stainless steel alloy has a different combination of qualities and attributes. However, the following are some of the main characteristics of a stainless steel:

- Durability: Stainless steel is a sturdy, long-lasting metal that can withstand mechanical harm.

- Chemical Resistance: Due to its resistance to oxidation and corrosion, this alloy is an excellent option for filters and other products that will come into contact with chemicals and water. Its relatively low carbon content further reduces its susceptibility to corrosion. As a result, even saltwater and oxidizing acids won't harm it.

- Workability: Stainless steel is incredibly formable, simple to manufacture and shape, and easy to clean without harm. It can be safely sanitized using various techniques, including dry vapor and steam cleaning.

- Strength and Mechanical Resistance: Stainless steel is renowned for its ability to withstand impacts, perform well, and maintain its physical properties in low-temperature settings. Stainless steel has no iron and is not magnetic.

Choosing the Correct Steel Mesh Supplier

To ensure you have the most positive outcome when purchasing steel mesh from a steel mesh supplier, it is important to compare several companies using our directory of steel mesh suppliers. Each steel mesh supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each steel mesh business using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple steel mesh companies with the same form.

Cold Headed Parts

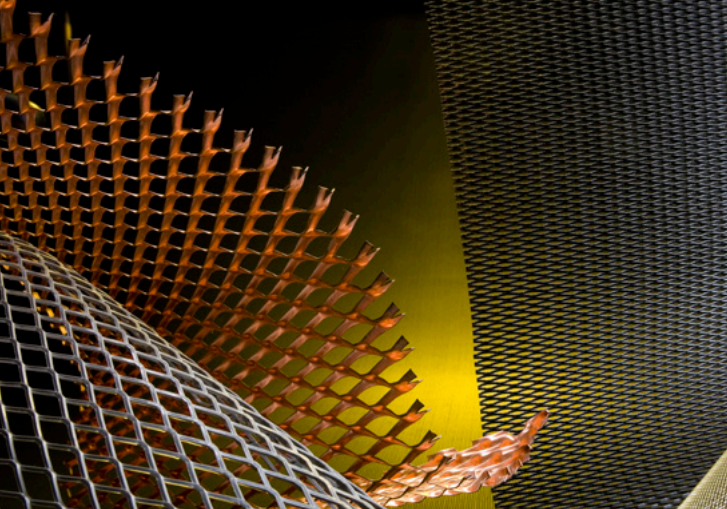

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services