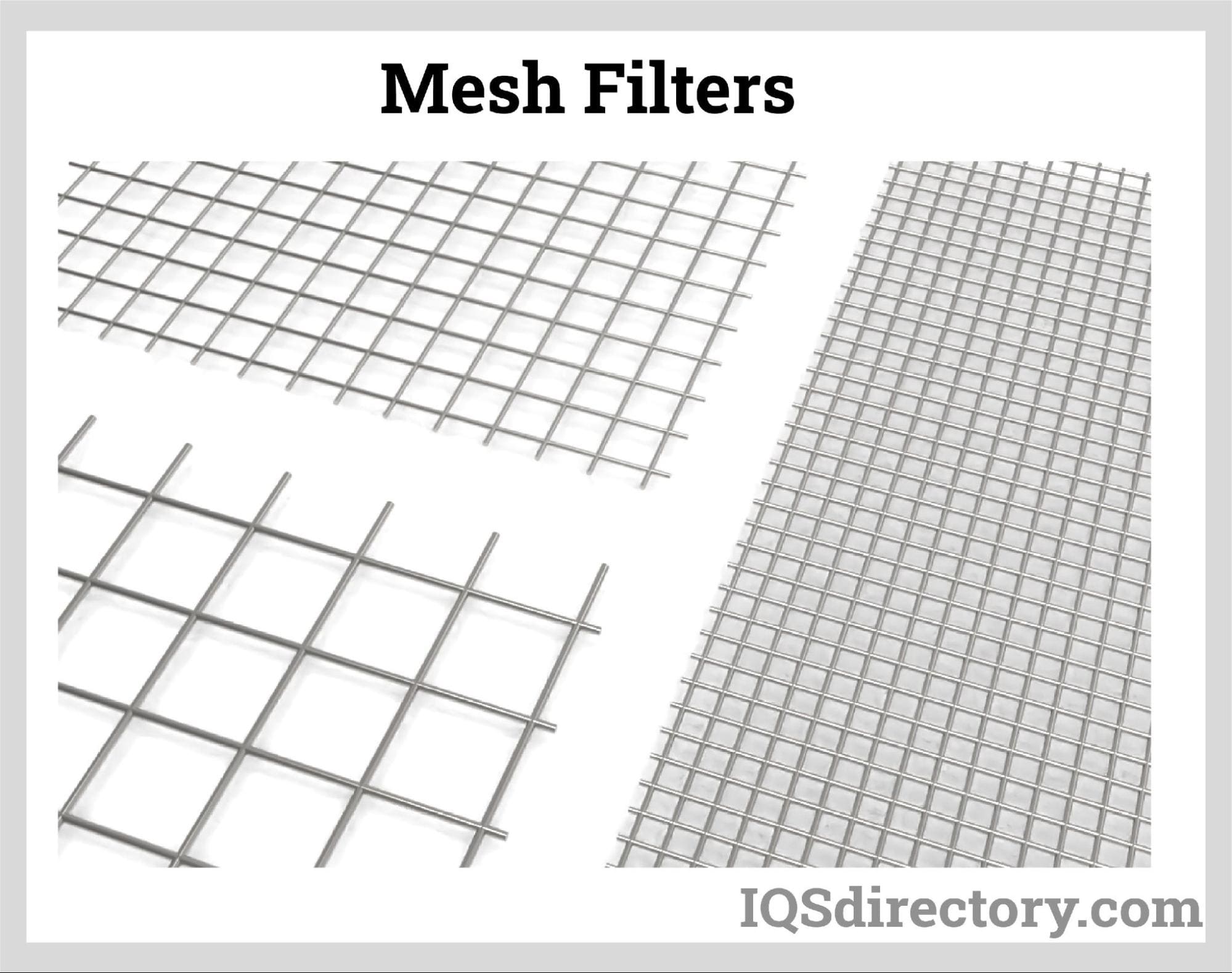

The term mesh filter refers to wire mesh stretched using metal threads and has small gaps between the various metal threads. Engineers can design mesh filters, a network of metallic wires that creates a flexible filter cloth, with precise, rigid pore holes to fit most filter systems. In addition, one of the strongest filter media is metal mesh filters. Anything too large to fit through the little spaces between the metal plates is caught in the mesh. Read More…

We’ve been a leading manufacturer and distributor of wire cloth/mesh for 70 years, sourcing and stocking North America’s largest selection of wire cloth products – over 5000 in our warehouse. We offer processing capabilities such as precision cutting, calendering, heat treating, cleaning and coating and weave domestically most alloys including brass, copper, Hastelloy, Monel and others into ...

Banker Wire is your quality-driven manufacturing partner for woven and welded wire mesh used in architectural and industrial applications. Our manufacturing expertise has been refined for over a century, bringing unmatched customization, quality, and service to our customers. Our products embody our commitment to providing the widest variety of wire cloth at an unbeatable value. Nowhere else will ...

For over 45 years, UWC has supplied quality mesh products for numerous industries with distinct applications. We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles. Our fabrication services comprise shearing, slitting and stamping options. In addition, we produce baskets, trays, cylinders,...

Marco Specialty Steel is a leading-supplier of wire cloth, wire cloth screens and wire mesh. Our warehouse maintains a wide range of wire cloth products in a variety of material grades and styles. We offer wire cloth in full rolls, cut-to-size pieces, slitting, circle cutting, blanking and stamping.

Hoyt Wire Cloth is a family-owned business that has been serving a variety of markets for over 50 years. We have experience producing wire cloth for industries such as coal, landscaping, concrete, gravel & sand, and more. Our line of wire mesh products includes self-cleaning screens, perforated plate, screening accessories, and more. If you have a design in mind call us and will manufacture what...

Since 1885, Phoenix Wire Cloth has been a wire cloth manufacturer of industrial wire cloth, welded wire cloth, wire mesh, stainless steel wire cloth and filter cloth. Phoenix Wire Cloth produces wire cloth for fences as well as safety and security equipment and supplies.

More Mesh Filter Manufacturers

While some filters are larger and only hold back massive particles in a stream, others are smaller and only let through the smallest particles. When choosing the mesh material, the filtration task's needs and the surrounding circumstances are considered. Grease may be filtered most effectively with this filter, especially if the range hood's filter is angled toward the table top. Metal meshes are among the most effective filter media because of their extremely high pore stability, limited pore size distribution, and strong mechanical strength.

Types of Mesh Filters

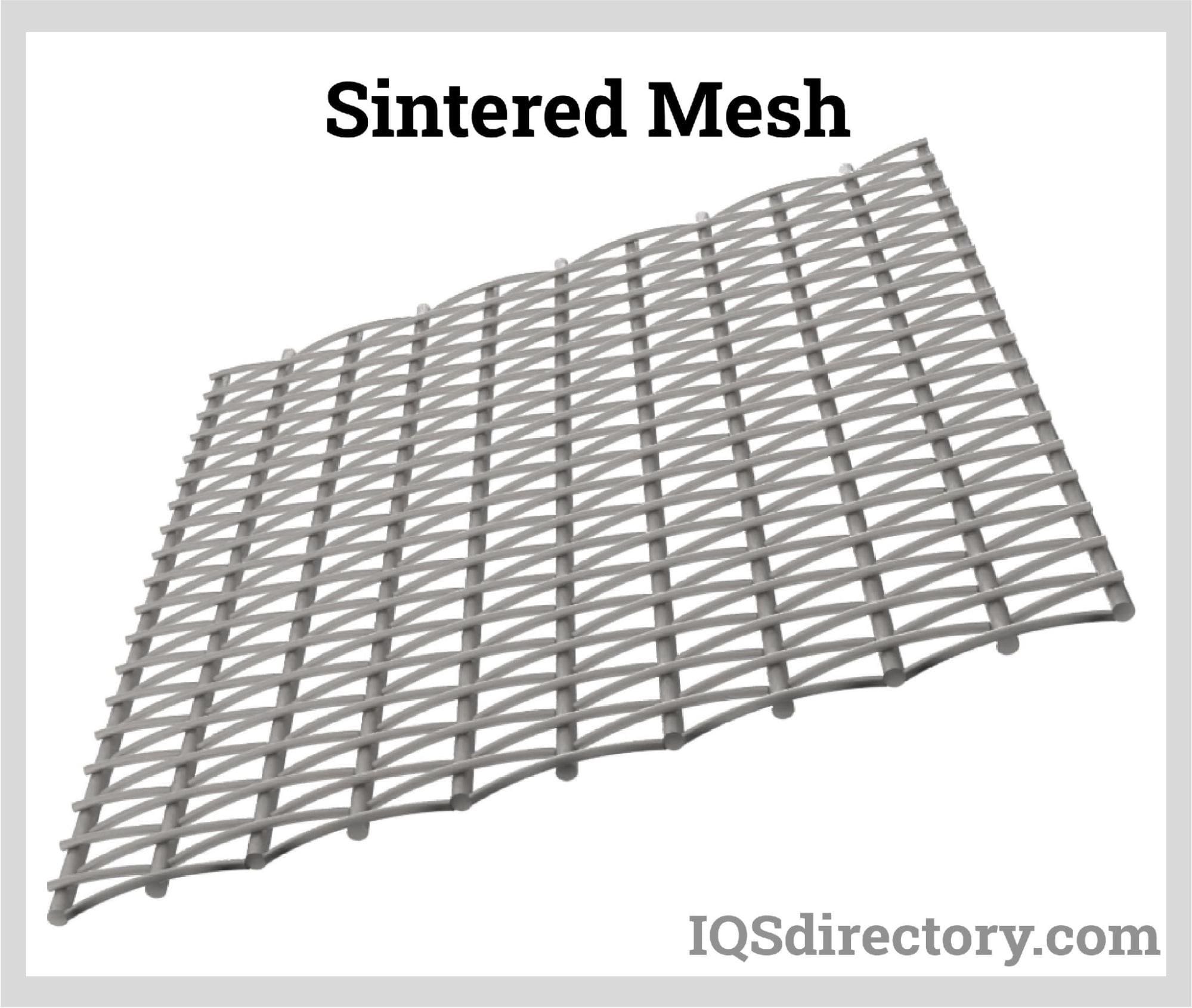

Sintered Mesh Filters

A "sintering" procedure creates a sintered mesh from one or more layers of woven wire mesh. A single-layer woven wire mesh is first uniformly roller flattened to achieve good contact at the wire crossover places. Special fixtures then laminate this calendared mesh’s single layer or multiple layers in a high-temperature furnace under mechanical pressure. The temperature of the furnace is increased to the point at which sintering (diffusion-bonded) takes place, and the furnace is filled with a proprietary inset gas. The mesh is stiffened after being subjected to controlled cooling.

Gas, air, dust, and liquid filtration require sintered material. Additionally, the (petro) chemical, water treatment, and pharmaceutical industries use sintered materials. A delicate inner mesh offers precise filtering within a shield of protection. Several mesh combinations can be created depending on how the filter is applied. Below are the specifications that may be altered in the mesh filter configuration.

Diameter: 2.0-500mm range

Height: 1 to 100 mm

Aperture Range: 0.1-120 um is the aperture range

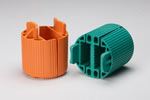

Laminated Metal Mesh Filters

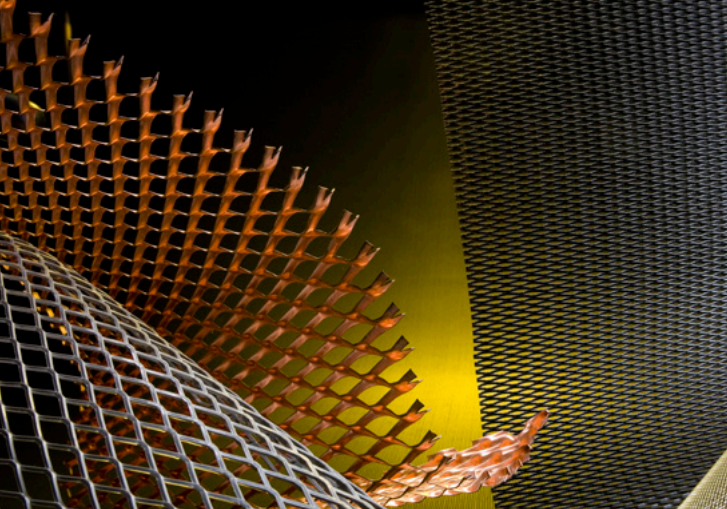

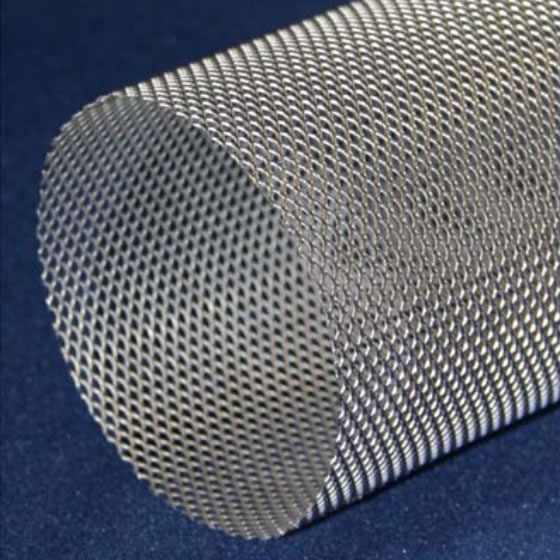

Mechanically unstable metal mesh can be merged with stronger meshes thanks to mesh laminates. These filters are constructed of galvanized wire mesh, copper mesh, stainless steel woven mesh, galvanized square eye mesh, and other metals. The most common metals used to make wire mesh filters for screening are copper, aluminum, brass, and bronze. Stainless steel is resistant to corrosion and high temperatures and produces a filter media that is extremely smooth and finely separating.

Stainless steel mesh is a great choice for withstanding high-impact and break-in attempts because of its qualities, particularly its high tensile strength and durability. Stainless steel mesh can withstand bullets and is virtually impossible to cut, gouge, or break.

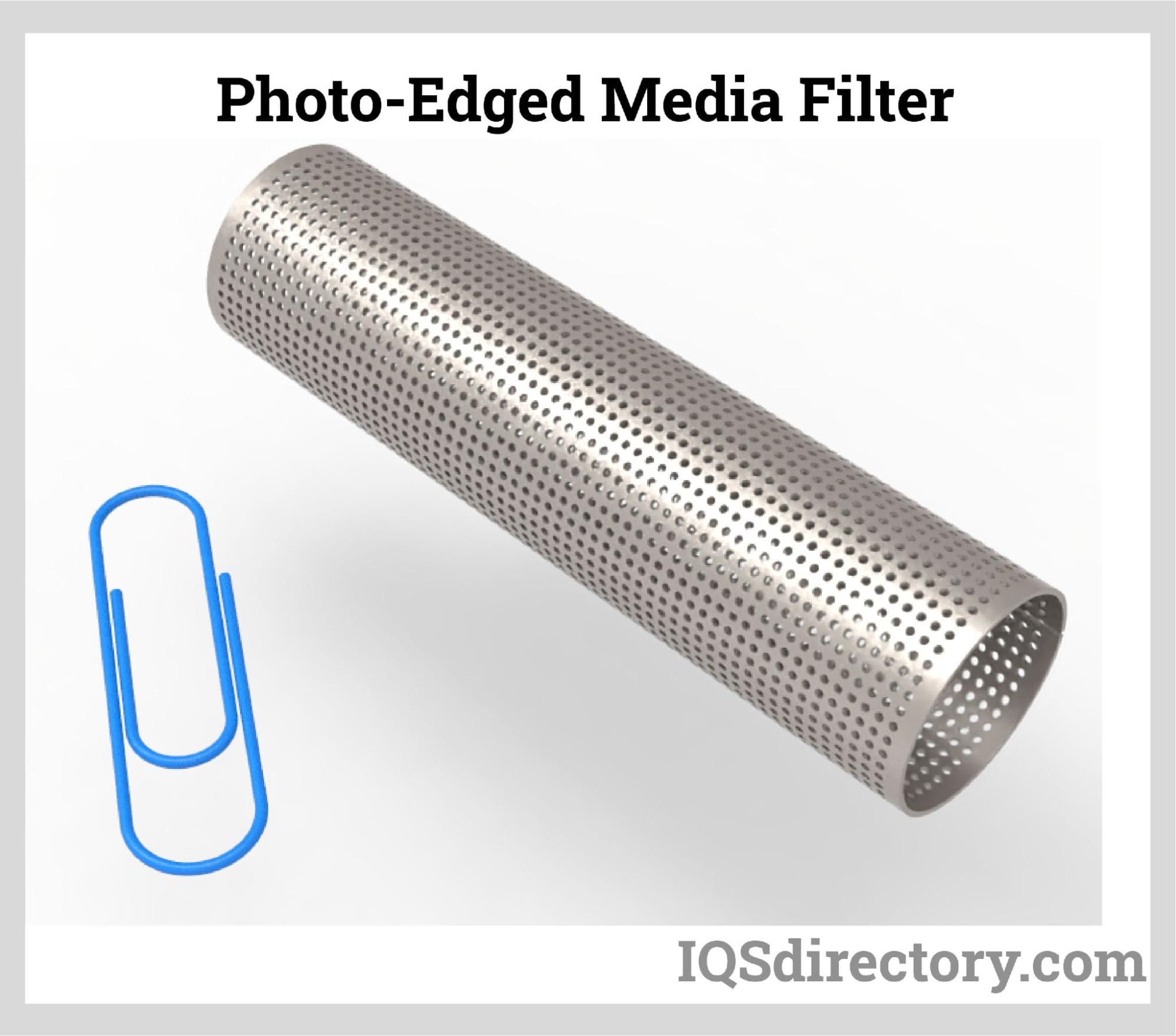

Photo-Etched Media Mesh Filters

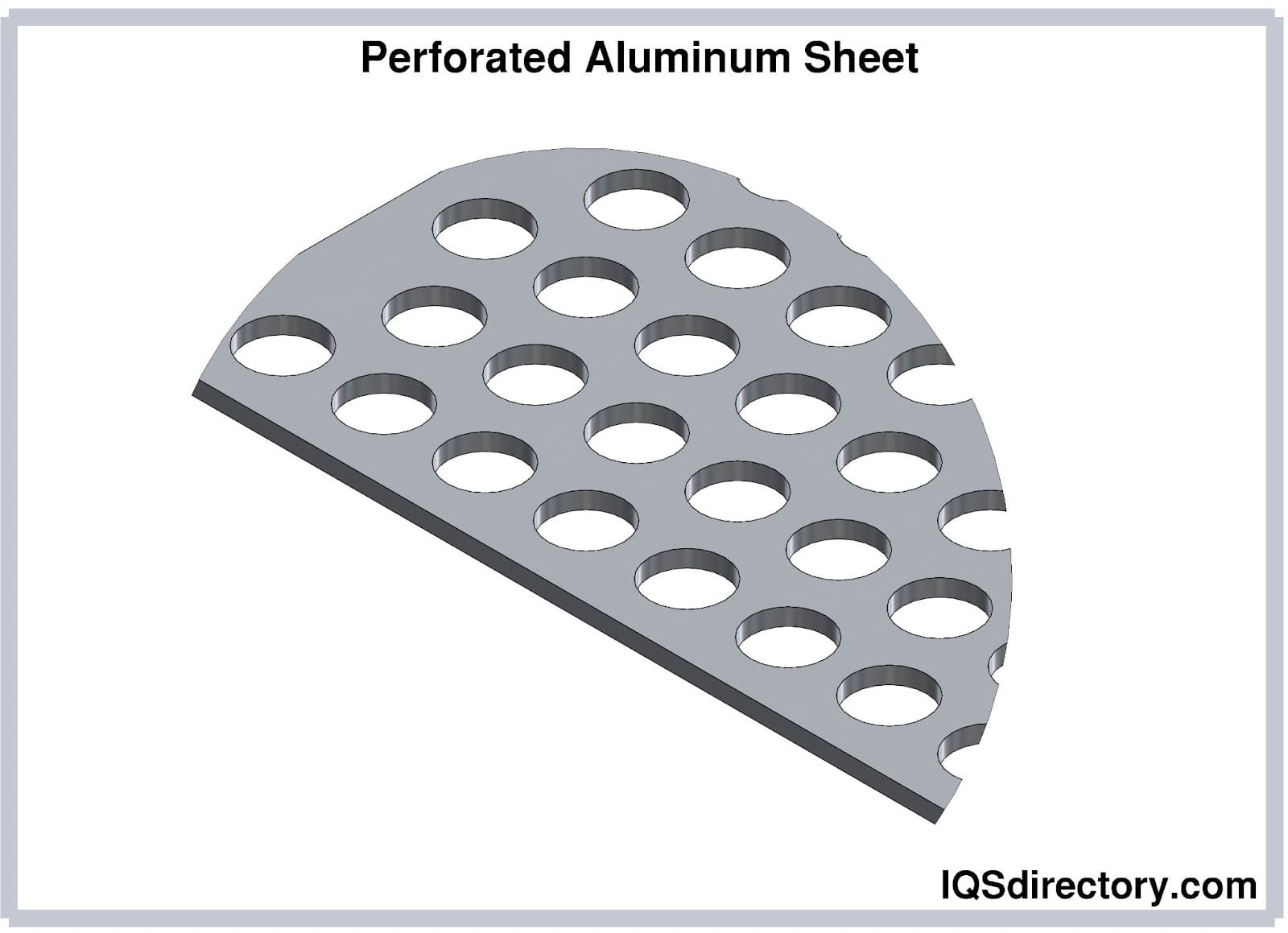

For various demanding applications and industries, including the medical, pharmaceutical, aerospace, automotive, and more, photo etching produces high-performance filter solutions. Photo-etched filters are created from a solid piece of thin metal sheet instead of filters made using conventional stamping techniques. Photo-etched filters have zero material or structural degradation, no burrs, and no stress. As a result, these filters are stronger, thinner, cleaner, more effective, and less prone to deterioration or unmasking.

Benefits of Mesh Filters

- Resistant to heat shock, particle bonding, and high temperatures up to 600 °F

- Excellent air permeability, even distribution, precise air permeability aperture, high flow rate, and effective filtration

- Beautiful and long-lasting integration

- The sintered filter has great mechanical strength and depth filtering because it comprises highly homogeneous, interconnected mesh pores with tortuous routes that leave solid particles in the gas or liquid.

- Some models can tolerate temperatures of up to 900 °F (482 ° C) in reducing environments and 750 °F (399 ° C) in oxidizing environments.

- The nano-scale stainless steel powder-sintered filter core's inner and outer tube walls are smooth and level, the pores are evenly spaced, and the filter core has good strength.

Applications of Mesh Filters

- Fixed photo-etched openings with more accurate and tighter hole-size tolerances, so that usage and flow characteristics do not impact on the pore size's integrity

- Filters with no burrs or stresses improve dimensional stability, lead to greater material integrity,provide excellent mechanical strength, and create precise hole geometry down to the micron level (as small as.003 inches).

- Describe several hole configurations, such as conical and cylindrical (straight) holes (tapered)

- Different aperture shapes can be used to regulate flow rates and obtain specified flow characteristics for particular purposes.

- Utilizing design flexibility, patterns and shapes can be as complex as the user requires.

- Design iterations and inexpensive tooling that enable quick design changes and meticulous attention to detail regarding complete blemish- and scratch-free surface finishes

- Almost any material, including thermal interface metals, can be used to create filters.

Choosing the Proper Mesh Filter Manufacturer

To ensure you have the most positive outcome when purchasing mesh filters from a mesh filter manufacturer, it is important to compare several companies using our directory of mesh filter manufacturers. Each mesh filter manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each mesh filter business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple mesh filter companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services